GunKraut

Senior Member

Occasionally I run into interesting things which need some time to start growing on me. One such thing is the G41, the Mighty Walther, an important step towards the development of the G43. Generally, I'm more of a K98 and G43 person because I prefer rifles I can take to the range and fire all day long without problems. According to what I read and heard, the Mighty Walther was quite the opposite of my general preference. G41's are regarded as finicky, unreliable, said to foul and break easily and parts are hard to come by; overall something I should stay away from. Oh, and they are said to be awfully expensive.

Lucky me, I found a "sporterized" 1943 G41 a-block for little money. The fore end had been chopped off and lost, upper hand guard, both barrel bands, bayonet lug and band spring were missing as well. All parts including the mutilated stock had matching serial numbers and were well cared for, all metal parts were clean and oil coated without any trace of rust. The bore was good and the gas system without the usual corrosion.

My first step was to get an original hand guard as a starting point for re-creating the missing fore end. I also needed the barrel bands in order to machine the correct shape of the fore end. The hand guard was provided by Terrill Biedenharn who not only owns an impressive collection of G41 rifles but also scours gun shows for spares to offer to other G41 owners. Although my rifle is an ac43, I settled for a duv hand guard to get the ball rolling. With the hand guard installed, I learned the stock had been shortened slightly past the step for the barrel band; not good as I now needed to add another piece to the stock. I ordered the missing metal parts from France. They are decent reproductions but not of breath taking quality and require different levels of detail work and fitting.

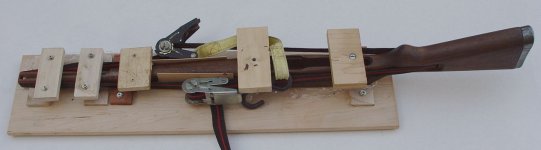

In order to get my power tools and fixtures set up for making a new fore end, I experimented with a 2x2 piece of pine (the final piece will be machined from laminated beech wood). It turned out pretty good given that other than some internet photos I had nothing to go by when I needed to route out the grooves for the band spring and the cleaning rod. Getting the cutout for the bayonet lug right was even more of a challenge. Now that I have a perfectly fitting pine fore end it provides me with all the relevantant dimensions needed for machining a laminate wood fore end.

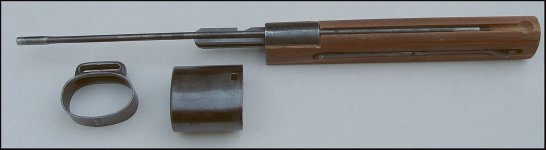

With a mock fore end on hand, I turned my attention to fabricating a less brittle hand guard then the original one I bought from Terrill. I had noticed similarities between my Springfield 03A3 hand guard and its G41 resin counterpart. I picked up a cheap 03A3 hand guard from Sergio of Northridge Inc, cut it up, added walnut strips to increase height and shaped it on a Craftsman router. I ordered brownish-red Resorcinol resin (nowadays called Cascophen) from Aircraft Spruce for gluing all pieces together. A lot of sanding using a Dremel sanding drum was necessary to allow the actuator rod to move freely underneath the hand guard. A dark ebony stain will hopefully make it look close to an original Walther part. In hindsight I should have probably just ordered a wooden hand guard from Lestek Fox... Well, the labor of love, or so they say.

I have attached a couple pictures of where I am right now. A laminate beech wood block has been created and is ready to be shaped into a new fore end. The only thing still bothering me is the rounded off tip of the mutilated stock where the fore end butts up against. I may have to chop the rounded portion off -about 1/8" to 3/16"- and add a laminate shim to re-create the step in the stock for the lower barrel band.

Lucky me, I found a "sporterized" 1943 G41 a-block for little money. The fore end had been chopped off and lost, upper hand guard, both barrel bands, bayonet lug and band spring were missing as well. All parts including the mutilated stock had matching serial numbers and were well cared for, all metal parts were clean and oil coated without any trace of rust. The bore was good and the gas system without the usual corrosion.

My first step was to get an original hand guard as a starting point for re-creating the missing fore end. I also needed the barrel bands in order to machine the correct shape of the fore end. The hand guard was provided by Terrill Biedenharn who not only owns an impressive collection of G41 rifles but also scours gun shows for spares to offer to other G41 owners. Although my rifle is an ac43, I settled for a duv hand guard to get the ball rolling. With the hand guard installed, I learned the stock had been shortened slightly past the step for the barrel band; not good as I now needed to add another piece to the stock. I ordered the missing metal parts from France. They are decent reproductions but not of breath taking quality and require different levels of detail work and fitting.

In order to get my power tools and fixtures set up for making a new fore end, I experimented with a 2x2 piece of pine (the final piece will be machined from laminated beech wood). It turned out pretty good given that other than some internet photos I had nothing to go by when I needed to route out the grooves for the band spring and the cleaning rod. Getting the cutout for the bayonet lug right was even more of a challenge. Now that I have a perfectly fitting pine fore end it provides me with all the relevantant dimensions needed for machining a laminate wood fore end.

With a mock fore end on hand, I turned my attention to fabricating a less brittle hand guard then the original one I bought from Terrill. I had noticed similarities between my Springfield 03A3 hand guard and its G41 resin counterpart. I picked up a cheap 03A3 hand guard from Sergio of Northridge Inc, cut it up, added walnut strips to increase height and shaped it on a Craftsman router. I ordered brownish-red Resorcinol resin (nowadays called Cascophen) from Aircraft Spruce for gluing all pieces together. A lot of sanding using a Dremel sanding drum was necessary to allow the actuator rod to move freely underneath the hand guard. A dark ebony stain will hopefully make it look close to an original Walther part. In hindsight I should have probably just ordered a wooden hand guard from Lestek Fox... Well, the labor of love, or so they say.

I have attached a couple pictures of where I am right now. A laminate beech wood block has been created and is ready to be shaped into a new fore end. The only thing still bothering me is the rounded off tip of the mutilated stock where the fore end butts up against. I may have to chop the rounded portion off -about 1/8" to 3/16"- and add a laminate shim to re-create the step in the stock for the lower barrel band.

Attachments

-

G41-1.jpg62.2 KB · Views: 223

G41-1.jpg62.2 KB · Views: 223 -

G41-2.jpg82.3 KB · Views: 191

G41-2.jpg82.3 KB · Views: 191 -

G41-3.jpg117.2 KB · Views: 153

G41-3.jpg117.2 KB · Views: 153 -

G41-4.jpg185.1 KB · Views: 154

G41-4.jpg185.1 KB · Views: 154 -

G41-5.jpg53.2 KB · Views: 136

G41-5.jpg53.2 KB · Views: 136 -

comparison1.jpg52.9 KB · Views: 140

comparison1.jpg52.9 KB · Views: 140 -

comparison3.jpg112.5 KB · Views: 132

comparison3.jpg112.5 KB · Views: 132 -

handguard0.jpg164.4 KB · Views: 118

handguard0.jpg164.4 KB · Views: 118 -

handguard1.jpg69.6 KB · Views: 117

handguard1.jpg69.6 KB · Views: 117 -

handguard2.jpg69.3 KB · Views: 120

handguard2.jpg69.3 KB · Views: 120

).

). !! I guess if it were me, I'd probably run a mag through it kind of slow, then empty a mag pretty quick just to see. I think it will be cool!

!! I guess if it were me, I'd probably run a mag through it kind of slow, then empty a mag pretty quick just to see. I think it will be cool!