You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The SMG FG42 In Detail

- Thread starter Wilhelm

- Start date

d dAY dOG

Well-known member

They are still being made as far as I know. I exchanged emails with Rick Smith at SMG just recently and he gave no indication that they are not making any more Type 2s. They are in development / pre-manufacturing stages for their upcoming FG42 Type 1 rifle, but that hasn't changed anything they are doing with the Type 2, to my knowledge.

You can find used SMG FG42s for sale on RARE occasions on Gun Broker or Guns America mostly. Sometimes new ones are sold by SNMG or by someone who bought a new one and is looking to make a buck. There was actually one for sale online at Cabela's a while back. Most of the used ones still sell for $5,000 or slightly north of that sum. I've never seen a used SMG FG42 Type 2 sell for under $5,000 online. I've also never seen a used one sell above $5,500. Early on I saw a new one sell for $7,000, but that was a long time ago and now the new ones I've seen out there sell north of $5,000.

Here's the page on Rick's web site that provides the method to go about buying one. http://smgguns.com/?page_id=591

However, it would be best to go to Rick's site and email him for a status of how long you may be looking to wait on the list or if there's been any changes in his operation that aren't updated on his web site yet.

Doug

You can find used SMG FG42s for sale on RARE occasions on Gun Broker or Guns America mostly. Sometimes new ones are sold by SNMG or by someone who bought a new one and is looking to make a buck. There was actually one for sale online at Cabela's a while back. Most of the used ones still sell for $5,000 or slightly north of that sum. I've never seen a used SMG FG42 Type 2 sell for under $5,000 online. I've also never seen a used one sell above $5,500. Early on I saw a new one sell for $7,000, but that was a long time ago and now the new ones I've seen out there sell north of $5,000.

Here's the page on Rick's web site that provides the method to go about buying one. http://smgguns.com/?page_id=591

However, it would be best to go to Rick's site and email him for a status of how long you may be looking to wait on the list or if there's been any changes in his operation that aren't updated on his web site yet.

Doug

Today, I took the FG42 out for the first since May of last year. I got to the range and a local C&R club was there so there was a decent number of people with a bunch of WWI and WWII firearms. One guy even had a semi auto 1919. As I walked down the line, people actually set their rifles down and got up to follow me. By the time I got to my bench, there was actually a crowd a people around me gawking and making "oohs" and "ahhs" sounds. I hate attention. So, I answered a bunch of questions (Where did you get that? , How much did it cost?, etc,) and made nice until everyone went back to what they were doing. I set my target up at 100 yards and loaded up two magazines. By the time I was halfway through my first magazine, there was a crowd again. Did I mention that I hate attention? The first magazine went off just fine. Magazine two, round thirteen.......the right bipod leg snaps at the axle and the muzzle falls flat on the bench. In the process, the bolt cycles but the round does not extract so a live round rams up into the back of the spent casing and rams the bullet into the case causing a jam. So, I pull the bolt back, remove the magazine, dump out the live round and let the bolt go home on the empty casing. I try to pull the bolt back to extract the spent casing and it's LOCKED....again. A 19-20 year old kid walks up to me with his $100 Mosin rifle that has been functioning perfectly and says, "That's some well built German steel ya got there. How much did you say you paid for that??" 20 minutes later, I'm home and the rifle has cooled down. The bolt opens easily and the empty casing falls out on my kitchen floor. After approx. 429 rounds through this thing, I'm done with commercial firearms. Pictures:

mostpeople

Senior Member

Looking to sell your Fg42? Mines been flawless, let me know if you wanna sell.

pitfighter

Senior Member

That is a bummer -

If it's any consolation the bipod legs are quite vulnerable to failure on the original, too.

They are not die-cast, so it's a different kind of failure - but, an Achilles heel for sure.

If it's any consolation the bipod legs are quite vulnerable to failure on the original, too.

They are not die-cast, so it's a different kind of failure - but, an Achilles heel for sure.

Yes, I know that the bipod was a weak point even on the originals and these are only cast aluminum. I can't really blame SMG for the breakage because IIRC, SHOEI made them. I've never been hard on this rifle but I would expect them to stand up to regular bench use. I'm also sure that Rick would send me a replacement if I asked him because his customer service has always been, to put it mildly, phenomenal. I sent an email to Estes Adams and asked if he would be willing to fabricate me a set out of steel. If he's unable or unwilling, I'll contact Rick. I really would rather have a steel set.

As for selling it......I REALLY don't want to. I LOVE the rifle despite the problems but I HATE problems! Rick has offered to go over the locking issue for free but I hesitate to ship it cross-country for fear that the shipping agent would "lose" it. I have REALLY, REALLY bad luck. I don't know....I just don't know.

I have an FN M249 on the way. We'll see how that holds up.....

As for selling it......I REALLY don't want to. I LOVE the rifle despite the problems but I HATE problems! Rick has offered to go over the locking issue for free but I hesitate to ship it cross-country for fear that the shipping agent would "lose" it. I have REALLY, REALLY bad luck. I don't know....I just don't know.

I have an FN M249 on the way. We'll see how that holds up.....

I sent an email to Estes Adams and asked if he would be willing to fabricate me a set out of steel. If he's unable or unwilling, I'll contact Rick. I really would rather have a steel set......

I am sure Estes could fabricate you a steel set but they would not look like what you got....that would invlove some steel stampings...and that would require a tool and die shop to manufacture a set of dies...and then a a shop with a press to stamp it...super duper expensive(like astronomical) for a one off stamping....hell even if he made a set for all the remaining original FG,s and every one SMG has produced it would still be prohibitively expensive I would think.

Might wanna think about not deploying the tripod legs @ the bench...prehaps get a an adjustable Caldwell front rest.

Would give you better accuracy...for what that is worth.

It'll be alright Willy...just take a deep breath...pull back and regroup.

HAHA.....thanks dude.

As a follow up, I was out for the evening but, when I got home, I saw that Rick had contacted me offering to send me another bipod leg. If I understand him correctly, he is telling me that I only have to sent the bolt back for adjustment and NOT the entire rifle. If that is correct, I will most definitely be sending the bolt bak with the broken leg. Again, this kind of customer service from SMG is above and beyond.

As a follow up, I was out for the evening but, when I got home, I saw that Rick had contacted me offering to send me another bipod leg. If I understand him correctly, he is telling me that I only have to sent the bolt back for adjustment and NOT the entire rifle. If that is correct, I will most definitely be sending the bolt bak with the broken leg. Again, this kind of customer service from SMG is above and beyond.

messerschmittfan

Well-known member

My FG42 number 34

Just a note on my SGM FG42; I have run over 800 rounds through mine, mostly off of the bi-pod without any problems. Some of those rounds were as fast as I could move the trigger and it sounded like automatic fire. Rich is a great guy that stands behind his product. Harry

Just a note on my SGM FG42; I have run over 800 rounds through mine, mostly off of the bi-pod without any problems. Some of those rounds were as fast as I could move the trigger and it sounded like automatic fire. Rich is a great guy that stands behind his product. Harry

sprat

Senior Member

I am in the middle of building or I should say re-building a swiss STG 57. I had Estes Adams do the trunnion work for me last year, because he is the sig guy/fg-42 guy. he did a great job.

several folks last week asked for his contact information

they contacted Mr Adams and asked him to do their trunnion work also, Mr Adam can not do the work anymore, due to the new ATF directive regarding gunsmithing concerning ITAR regs

so Mr Adams is not un willing, but thanks to the POTUS or POS, he can no longer do this type of work.

several folks last week asked for his contact information

they contacted Mr Adams and asked him to do their trunnion work also, Mr Adam can not do the work anymore, due to the new ATF directive regarding gunsmithing concerning ITAR regs

so Mr Adams is not un willing, but thanks to the POTUS or POS, he can no longer do this type of work.

I put 20 more rounds through my .308 FG42 which puts me a little under 300 rounds total. I've only run my rifle on highest gas setting for the first 50 or so rounds and decided to move it to the middle setting and it has run 100% ever since...not that I had any malfunctions but I'm just putting it out there that adjusting it down hasn't negatively effected its function. I did notice that the recoil and ejection on the high setting was on the excessive side and I really didn't want to worry about damage or breakage so I didn't see any harm in trying a different setting. Now the operation is super smooth and the ejection isn't nearly as violent. The trigger pull is still on the heavy side but has smoothed out considerably.

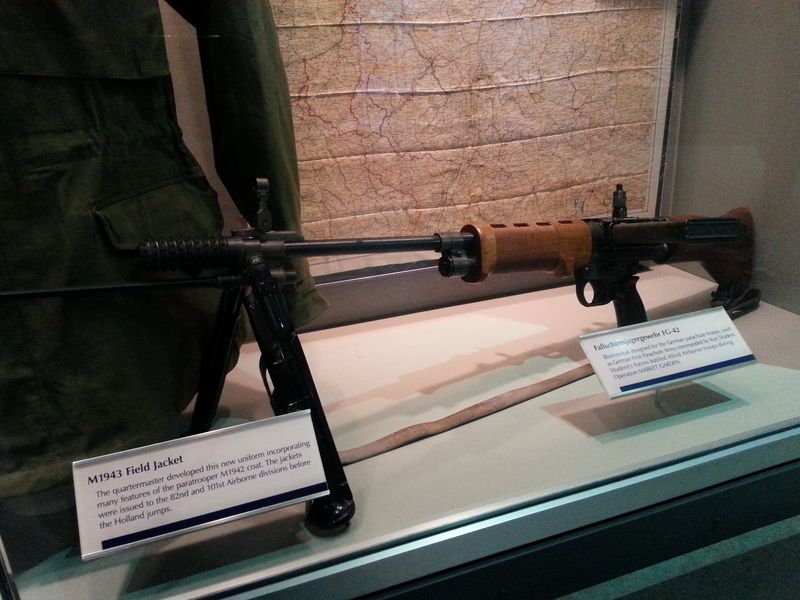

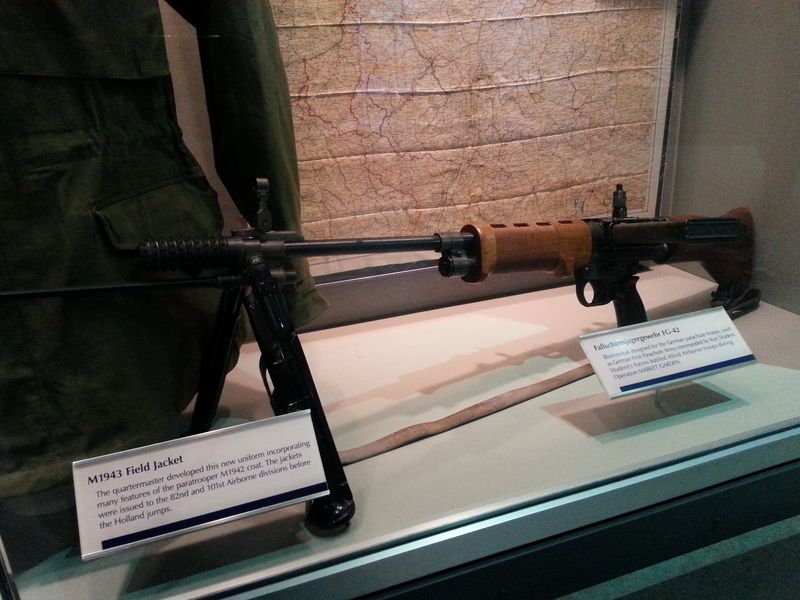

This is an original Type G on display at the Airborne & Special Operations Museum here in Fayetteville

This is an original Type G on display at the Airborne & Special Operations Museum here in Fayetteville

Today, I received my bolt and replacement bipod leg back from Rick Smith at SMG. I figured that, while I was sending the bipod leg back for replacement, I might as well send the bolt in for resizing too because Rick says that will clear up the lockup issue I have been experiencing with a hot rifle since it was new. I sent the parts out to him via registered mail and he must have begun work on them as soon as they arrived because he contacted me just a couple days (at most) after receiving them to tell me that they were ready to be shipped back. They arrived via FedEx packed just literally exactly as I had shipped them to him. He used the same box and even the same packing material. This was perfectly fine by me as I tend to over-pack things for protection. When I unwrapped the parts, I was pretty amazed at what I saw. I expected the bipod leg to be new and it was so no surprise there. What amazed me was the bolt. It's 100% guaranteed my bolt but it looked absolutely new. I had cleaned it off with carb cleaner prior to sending it in to Rick so that he wouldn't get a funky bolt to work on but the wear marks were a bright silver and contrasted with the overall dull grey finish on the part. I don't know what Rick did but, while the wear marks can still be seen upon close inspection, the finish is back as it was when new. Perhaps he bead blasted it? I don't know but the work is VERY professional As an example, here's what the cam slot looked like when I sent it in:

You can clearly see the bright spot where the cam on the carrier rubs.

Now, here is what that area looks like now:

Schweet! To be clear, it doesn't appear that any metal was removed. No polishing or work of any kind appears to have been done. It's just that, whatever SMG did, the original look of the finish was restored. Of course, one range trip will put it back to how it was; I just want to impart how thorough it appears Rick is. This is Excellent attention to detail and that equates to Excellent customer service.

Here's the bolt overall:

Rick also replaced the extractor spring. He said that the one on it seemed a little weak.

A few close-ups:

This brings me to what was actually done to the bolt. According to Ricks' email, he "updated" it. What this means, I think, is that he ground the bolt down in some areas to give just a bit more clearance between it and the trunnion at the front while also reducing the rear collar a hair where it rides in the receiver. I hate to use the words "ground the bolt". That sounds rough and like a rig job. Rather, he appears to have reshaped it only where necessary paying VERY close attention not to touch the locking lugs. He also blended in the work so as to make it almost invisible. Only under close scrutiny can you even tell that any work was done.

For example, in the picture below, can you tell where the bolt was resized?

I myself am not 100% sure but I think I can see it. To the left of the picture and stopping approximately where the stitching on the zeltbahn intersects the bolt, you can see fine annular rings where the part was turned in a lathe. To the right of the stitching, those rings disappear. That is where the resizing was done......I think. The work is so finely done that I cannot be 100% sure. Below are four pictures showing all four sides of the bolt. I have used a China marker to show the areas where it appears Rick did his thing:

At least, that's my best guess. So thank you Rick Smith for standing behind your product! This kind of customer service and this level of Quality speaks volumes about your Integrity with a capital "I". This weekend, I plan on taking this thing back out to the range with another 100 rounds. Hopefully, the lock up problem is now gone. Of course, I'll post my findings.

In the next post, I'll show you guys the new bipod leg.

You can clearly see the bright spot where the cam on the carrier rubs.

Now, here is what that area looks like now:

Schweet! To be clear, it doesn't appear that any metal was removed. No polishing or work of any kind appears to have been done. It's just that, whatever SMG did, the original look of the finish was restored. Of course, one range trip will put it back to how it was; I just want to impart how thorough it appears Rick is. This is Excellent attention to detail and that equates to Excellent customer service.

Here's the bolt overall:

Rick also replaced the extractor spring. He said that the one on it seemed a little weak.

A few close-ups:

This brings me to what was actually done to the bolt. According to Ricks' email, he "updated" it. What this means, I think, is that he ground the bolt down in some areas to give just a bit more clearance between it and the trunnion at the front while also reducing the rear collar a hair where it rides in the receiver. I hate to use the words "ground the bolt". That sounds rough and like a rig job. Rather, he appears to have reshaped it only where necessary paying VERY close attention not to touch the locking lugs. He also blended in the work so as to make it almost invisible. Only under close scrutiny can you even tell that any work was done.

For example, in the picture below, can you tell where the bolt was resized?

I myself am not 100% sure but I think I can see it. To the left of the picture and stopping approximately where the stitching on the zeltbahn intersects the bolt, you can see fine annular rings where the part was turned in a lathe. To the right of the stitching, those rings disappear. That is where the resizing was done......I think. The work is so finely done that I cannot be 100% sure. Below are four pictures showing all four sides of the bolt. I have used a China marker to show the areas where it appears Rick did his thing:

At least, that's my best guess. So thank you Rick Smith for standing behind your product! This kind of customer service and this level of Quality speaks volumes about your Integrity with a capital "I". This weekend, I plan on taking this thing back out to the range with another 100 rounds. Hopefully, the lock up problem is now gone. Of course, I'll post my findings.

In the next post, I'll show you guys the new bipod leg.

Now on to the new leg. not much to see really; it just looks like the old one:

Here, we see the steel collar that SMG presses into the axle hole so that you don't have aluminum riding on steel as you pivot the leg:

I inquired about buying a spare set of legs so that I have some on hand should this happen again. Rick told me that wile he's not opposed to selling me a pair, each leg is hand fitted so that they position where they should both stowed and extended. The reason he needed the old leg back was so that he could match the new one to the old one. That is evidenced in the pictures below. You can clearly see where the leg was ground to the right of the detent plunger hole:

The bare aluminum between the detent plunger hole and the axle hole appears to just be a lack of paint. These legs are sourced from SHOEI. SMG is aware that they are a weak point in the design. As a matter of fact, even the original steel legs were prone to bending and breakage. Both war time trials by the Germans and post war testing by the United States cited how weak the legs were. I'm not making excuses for SMG. I wish these were made out of steel but, even if they were, they would be fragile. According to Rick, he tried to source stamped steel legs from multiple vendors but was quoted a price of $45,000 per 300 pair and that was the LOWEST quote! Stamped parts are cheap and cost effective.......if you making them by the millions. Otherwise, the price is horrendous. Someone suggested to me that I should only use them for static display and not range use. I asked Rick about that and he said,

"They will not stand up to being pulled back under tension before firing or dropping prone on them but they will serve as a shooting barrel support for a long time from what users tell us. Please use it when you want to and we will fix it when it fails."

I don't think a customer can ask for more fair treatment than that.

Here, we see the steel collar that SMG presses into the axle hole so that you don't have aluminum riding on steel as you pivot the leg:

I inquired about buying a spare set of legs so that I have some on hand should this happen again. Rick told me that wile he's not opposed to selling me a pair, each leg is hand fitted so that they position where they should both stowed and extended. The reason he needed the old leg back was so that he could match the new one to the old one. That is evidenced in the pictures below. You can clearly see where the leg was ground to the right of the detent plunger hole:

The bare aluminum between the detent plunger hole and the axle hole appears to just be a lack of paint. These legs are sourced from SHOEI. SMG is aware that they are a weak point in the design. As a matter of fact, even the original steel legs were prone to bending and breakage. Both war time trials by the Germans and post war testing by the United States cited how weak the legs were. I'm not making excuses for SMG. I wish these were made out of steel but, even if they were, they would be fragile. According to Rick, he tried to source stamped steel legs from multiple vendors but was quoted a price of $45,000 per 300 pair and that was the LOWEST quote! Stamped parts are cheap and cost effective.......if you making them by the millions. Otherwise, the price is horrendous. Someone suggested to me that I should only use them for static display and not range use. I asked Rick about that and he said,

"They will not stand up to being pulled back under tension before firing or dropping prone on them but they will serve as a shooting barrel support for a long time from what users tell us. Please use it when you want to and we will fix it when it fails."

I don't think a customer can ask for more fair treatment than that.

No pictures to post, just an update. Since the bolt was reworked, I have put 209 rounds through the FG42 on three separate occasions. The locking bolt problem has been entirely eliminated. A bonus of the bolt being reworked is that it is also now easier to charge the rifle even when cold. The first time after rework, I had two failures to extract which caused the next to rounds to be destroyed as the bolt tried to force them unto the rear of the non-extracted round. I found that curious because the extractor spring had been replaced while the bolt was with Rick (he said it seemed a bit weak). But it has not happened again so I'm just chalking that up to coincidence.

The second time out, I was testing magazines and had one jam (round 16 or 17 from the top of a full mag) but I'm certain that was due to a weak magazine spring. As I was trying to clear the jam, I could not get the action opened no matter how hard I pulled. Then I noticed that the charging handle had come part way out of the oprod and was tearing some new chunks out of the idiot mark I had put in the handguard way back at the beginning of this adventure. How it came loose, I do not know but I cannot discount operator error the last time I put it together so I'll take the blame. After I disassembled the rifle and fiddled with it for a few minutes, I got it open and the mangled round fell out. The charging handle is fine and everything seems to be in order so I put it back together and kept on going. No more problems.

The last time out was just a few days ago. I was again testing magazines and I had two jams which I am again sure was the result of a weak spring. The magazines are the weakest part of the equation. You have to remember that they at 70-80 years old (or more) and some of them are just plain worn out.

Ejection remains steady with spent casings being ejected at an approximately 45 degree angle and landing in the grass about 10-12 feet away. Some of the cases get mangled necks while others are still perfectly round. Almost all bear a small dent along the side of the case.

I noticed this last time out that the screw on the replaced bipod leg was working its way loose from recoil. This is not good as a wobbly leg will most likely result in a destroyed leg. I did not re-peen it as I don't want to screw up so I have used blue locktite. That has worked on the scope ring screws so I'll try it here and keep an eye on it. DO NOT use red locktite as it cannot be loosened without heating the parts! If it doesn't work, I'll have to try re-peening.

The new sear has a few marks on it but it's still pretty smooth. It's still heavy and it's not perfect but it does seem to be holding up far better then the first one.

So......currently I am at 639 rounds. A this point, every jam I am having seems to be caused by a weak magazine spring. I am starting to think that the rifle is now sorted out and I am hopeful that the last 361 will be trouble free. I will keep you updated.

The second time out, I was testing magazines and had one jam (round 16 or 17 from the top of a full mag) but I'm certain that was due to a weak magazine spring. As I was trying to clear the jam, I could not get the action opened no matter how hard I pulled. Then I noticed that the charging handle had come part way out of the oprod and was tearing some new chunks out of the idiot mark I had put in the handguard way back at the beginning of this adventure. How it came loose, I do not know but I cannot discount operator error the last time I put it together so I'll take the blame. After I disassembled the rifle and fiddled with it for a few minutes, I got it open and the mangled round fell out. The charging handle is fine and everything seems to be in order so I put it back together and kept on going. No more problems.

The last time out was just a few days ago. I was again testing magazines and I had two jams which I am again sure was the result of a weak spring. The magazines are the weakest part of the equation. You have to remember that they at 70-80 years old (or more) and some of them are just plain worn out.

Ejection remains steady with spent casings being ejected at an approximately 45 degree angle and landing in the grass about 10-12 feet away. Some of the cases get mangled necks while others are still perfectly round. Almost all bear a small dent along the side of the case.

I noticed this last time out that the screw on the replaced bipod leg was working its way loose from recoil. This is not good as a wobbly leg will most likely result in a destroyed leg. I did not re-peen it as I don't want to screw up so I have used blue locktite. That has worked on the scope ring screws so I'll try it here and keep an eye on it. DO NOT use red locktite as it cannot be loosened without heating the parts! If it doesn't work, I'll have to try re-peening.

The new sear has a few marks on it but it's still pretty smooth. It's still heavy and it's not perfect but it does seem to be holding up far better then the first one.

So......currently I am at 639 rounds. A this point, every jam I am having seems to be caused by a weak magazine spring. I am starting to think that the rifle is now sorted out and I am hopeful that the last 361 will be trouble free. I will keep you updated.

Last edited:

On August 22nd, I took the FG42 out for a light range day, just 40 rounds. I loaded up two magazines with 1970 FNM (Portugese) ammo and had at it. First magazine, zero problems and normal ejection (about 45 degrees toward the front and about 12 feet distant). Second magazine was chugging along normally too until round 14 (approximately round 673 total so far) when something didn't seem quite right. There seemed to be more flash than normal and the recoil seemed heavier too.....exactly as it did when I removed the muzzle brake earlier on.....better take a look up front. HEY!!!! where did my muzzle brake go?? The threaded part of it is still on the barrel but the majority is completely gone!! I unloaded the rifle, checked the internals for damage and looked down the barrel. Everything looked normal except for the missing brake. Well, I still had 6 rounds left so I put it back together and finished the magazine. You can really see and feel the difference firing without one, that's for sure. The last six round went off without a hitch. At this point, I am certain the sticky bolt problem has been rectified and reliability is good. There were two other guys at the range and they helped me walk the freshly mowed field for a solid hour looking for the remnants of the brake but we never did find it. I even came back just a bit before dark with my honey and she helped me look for another 20-30 minutes with no luck. Maybe it's in orbit for all I know! The only bit I did find was a tiny sliver right after it happened and that was somehow BEHIND me about 2 feet and 2 feet to my left. I couldn't help but laugh. Like most little kids, I often get a chuckle out of things getting destroyed....I can't help it! I wish I could have found it as it would have made a neato souvenir.....oh well. Anywho, when I got home I snapped a few pictures before cleaning:

Here is the muzzle with what's left of the brake still attached:

Notice that it broke away pretty clean right at the first set of holes.

The threads seem to be unaffected:

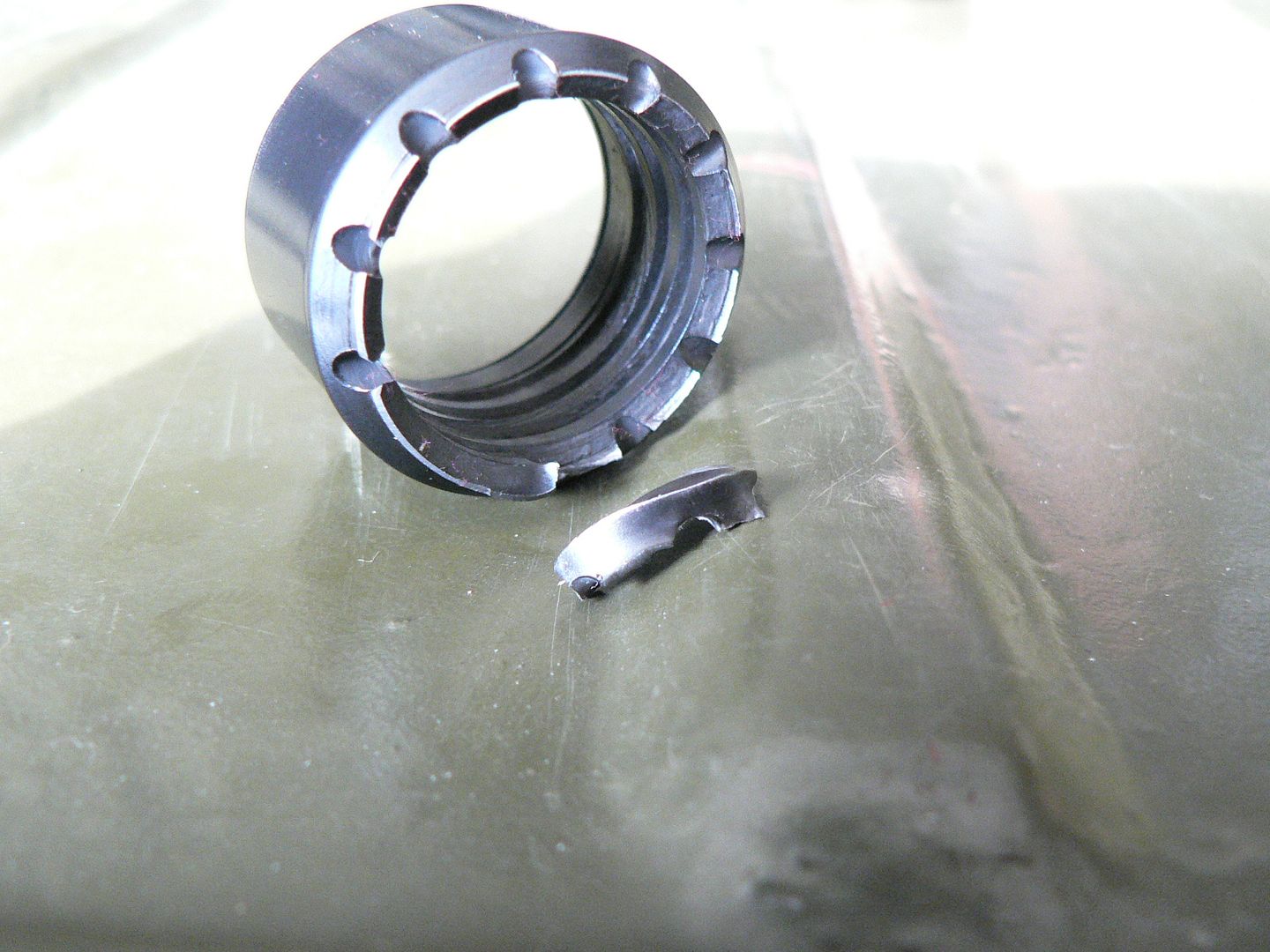

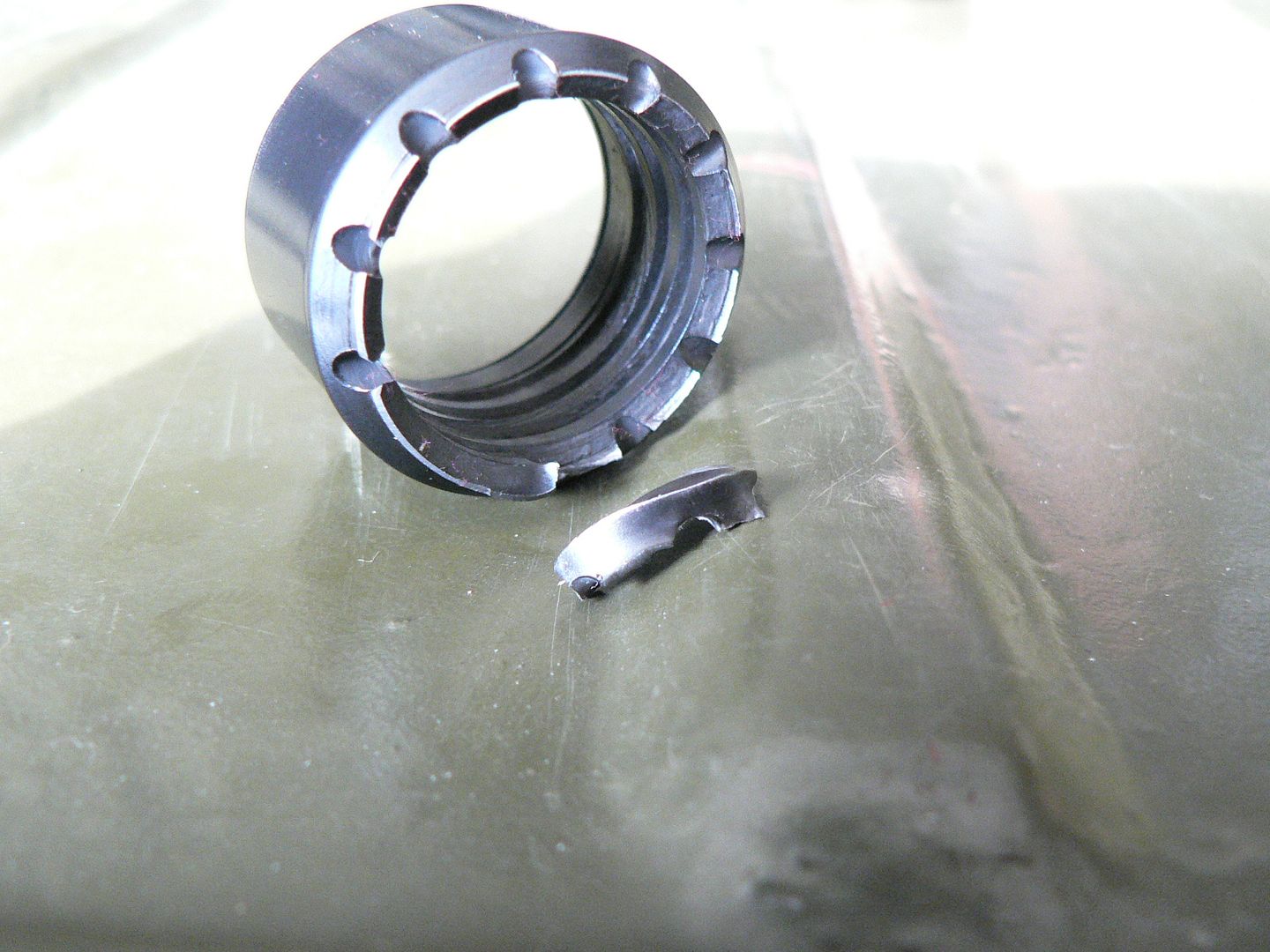

Here are a couple shots of it removed and the little sliver I found behind me:

When I contacted Rick Smith, he was very apologetic; explaining that some of the early brakes made had been cut with deep threads leaving the walls too thin and causing exactly the type of failure that had happened to me. He thought he had culled all of them out prior to shipping and said that, of the over 200 rifles sold to date, this has happened only one other time. Still finding the whole occurrence funny, I told him that no apologies were necessary and thanked him for his offer of replacing the brake even though the rifle is long out of warranty. All he asked was that I send him the threaded remains so that he could match the threads to a replacement thus ensuring that it would be neither sloppy nor tight on my rifle. He also ensured me that the new part would have thicker walls which should eliminate the possibility of this happening in the future.

Within days of receiving the old part, a new one arrived in the mail and it's just as good looking as the old one. There is absolutely no wobble on the threads yet it spins on smooth as the stem on a Rolex. I haven't had it out to the range yet but I should get to that next weekend:

As explained way back in this write-up, the numbers on the part, "124" in this case, have nothing to do with the serial number but rather are assembly numbers so that the threaded adapter and brake can be kept mated during assembly. Mr. Smith says that regardless of how careful you are in cutting of the threads, they barrel adapter and brake still need to be matched up by hand to ensure the best possible fit. Yes, it sucks that the part failed in the first place but the fact that Rick was straight forward about the cause and immediately offered to make it right without even being asked speaks volumes about his Integrity and Commitment to his customers. In my opinion, this is another case of absolutely rock solid customer support by SMG. THANK YOU MR. SMITH.

Here is the muzzle with what's left of the brake still attached:

Notice that it broke away pretty clean right at the first set of holes.

The threads seem to be unaffected:

Here are a couple shots of it removed and the little sliver I found behind me:

When I contacted Rick Smith, he was very apologetic; explaining that some of the early brakes made had been cut with deep threads leaving the walls too thin and causing exactly the type of failure that had happened to me. He thought he had culled all of them out prior to shipping and said that, of the over 200 rifles sold to date, this has happened only one other time. Still finding the whole occurrence funny, I told him that no apologies were necessary and thanked him for his offer of replacing the brake even though the rifle is long out of warranty. All he asked was that I send him the threaded remains so that he could match the threads to a replacement thus ensuring that it would be neither sloppy nor tight on my rifle. He also ensured me that the new part would have thicker walls which should eliminate the possibility of this happening in the future.

Within days of receiving the old part, a new one arrived in the mail and it's just as good looking as the old one. There is absolutely no wobble on the threads yet it spins on smooth as the stem on a Rolex. I haven't had it out to the range yet but I should get to that next weekend:

As explained way back in this write-up, the numbers on the part, "124" in this case, have nothing to do with the serial number but rather are assembly numbers so that the threaded adapter and brake can be kept mated during assembly. Mr. Smith says that regardless of how careful you are in cutting of the threads, they barrel adapter and brake still need to be matched up by hand to ensure the best possible fit. Yes, it sucks that the part failed in the first place but the fact that Rick was straight forward about the cause and immediately offered to make it right without even being asked speaks volumes about his Integrity and Commitment to his customers. In my opinion, this is another case of absolutely rock solid customer support by SMG. THANK YOU MR. SMITH.

Last edited:

pitfighter

Senior Member

Great photos and great customer service!

Interesting problem - could there have been a slight tumble from the projectile - - ?

Interesting problem - could there have been a slight tumble from the projectile - - ?

KDF82

Senior Member

Great photos and great customer service!

Interesting problem - could there have been a slight tumble from the projectile - - ?

Good point Pit.. Wish a camera had been watching. Get a metal detector maybe Brian?.. Having blown up lots of stuff for fun and profit, would be interesting to find the remains. FG42 forensic files.. Ha Ha

As for SMG and Rick, there is almost no equal in the replica German firearms manufacturing realm. If this had happened to a PTR44 nobody would be surprised!

Today I put another 63 rounds of Portuguese surplus through the rifle bringing my total up to 742 rounds. The odd number is the result of my finishing up the last of my 1965 dated stock. I am happy to report that the muzzle brake is still attached and I had no problems at all. That makes about 300 rounds now jam free other than a couple that were the result of weak magazine springs. The two magazines that are numbered to the rifle work perfectly. Any weak springs that I am encountering are from other magazines that I have picked up along the way. I really think that the sticking bolt was a large part of the various stoppage issues I was having. I believe that so much energy was being used up just unlocking the bolt that there was minimal left to properly cycle the action. Couple the reworked bolt with the remaining parts wearing in and I think ( I hope I don't jinx myself) I'm in the clear reliability wise. 258 rounds to go.

To answer your question pitfighter......No, I am certain the round came out of the barrel true and did not strike the brake as it hit where I was aiming at 125 yards. Rick assured me that the problem was a defective part and not the result of faulty ammunition. According to him, the round was guaranteed already past the end of the muzzle brake before it broke off and disappeared into Valhalla.

Also.....now that I my computer is up and running, I will be back to work on the SSD MP44 essay soon. I just haven't had a good block of time to sit down and work on it.

To answer your question pitfighter......No, I am certain the round came out of the barrel true and did not strike the brake as it hit where I was aiming at 125 yards. Rick assured me that the problem was a defective part and not the result of faulty ammunition. According to him, the round was guaranteed already past the end of the muzzle brake before it broke off and disappeared into Valhalla.

Also.....now that I my computer is up and running, I will be back to work on the SSD MP44 essay soon. I just haven't had a good block of time to sit down and work on it.