Here's a detail shot of the ejector slot:

Here are a couple photos of the cam slot showing what is again NORMAL wear:

SMG says in the video included with each rifle that you may even start to see chips of metal missing in this area over time. Apparently, it is normal so don't wig out when this starts to happen. Just keep shooting. SMG has over 15,000 rounds through their test rifle so I'll just take their word for it. I know I'll probably never put 15K through mine unless one of you want's to donate some ammo. I don't know what the black marks are in the wear area. It doesn't rub off so I just ignore it.

Let's take the extractor apart. Here it is assembled:

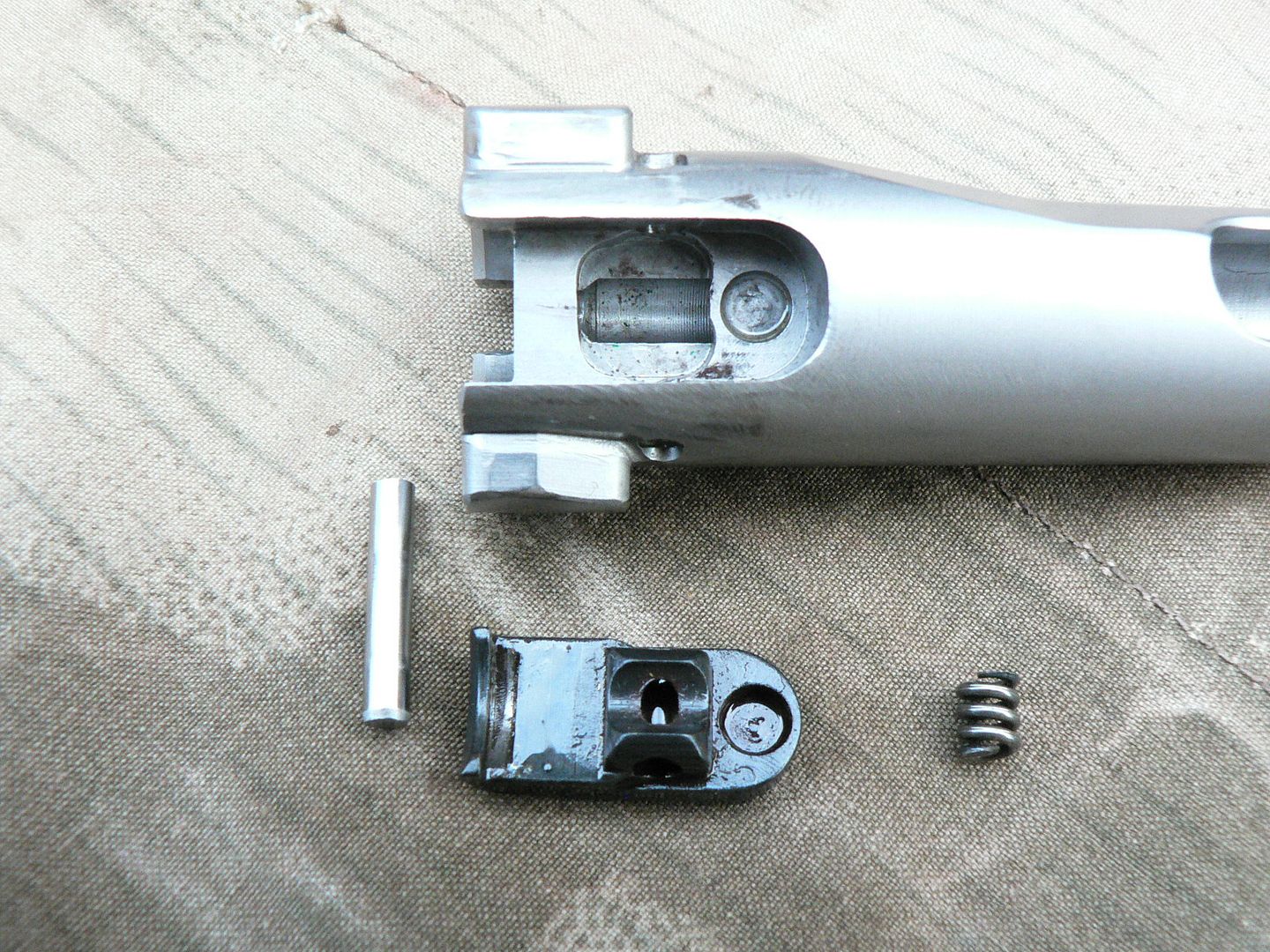

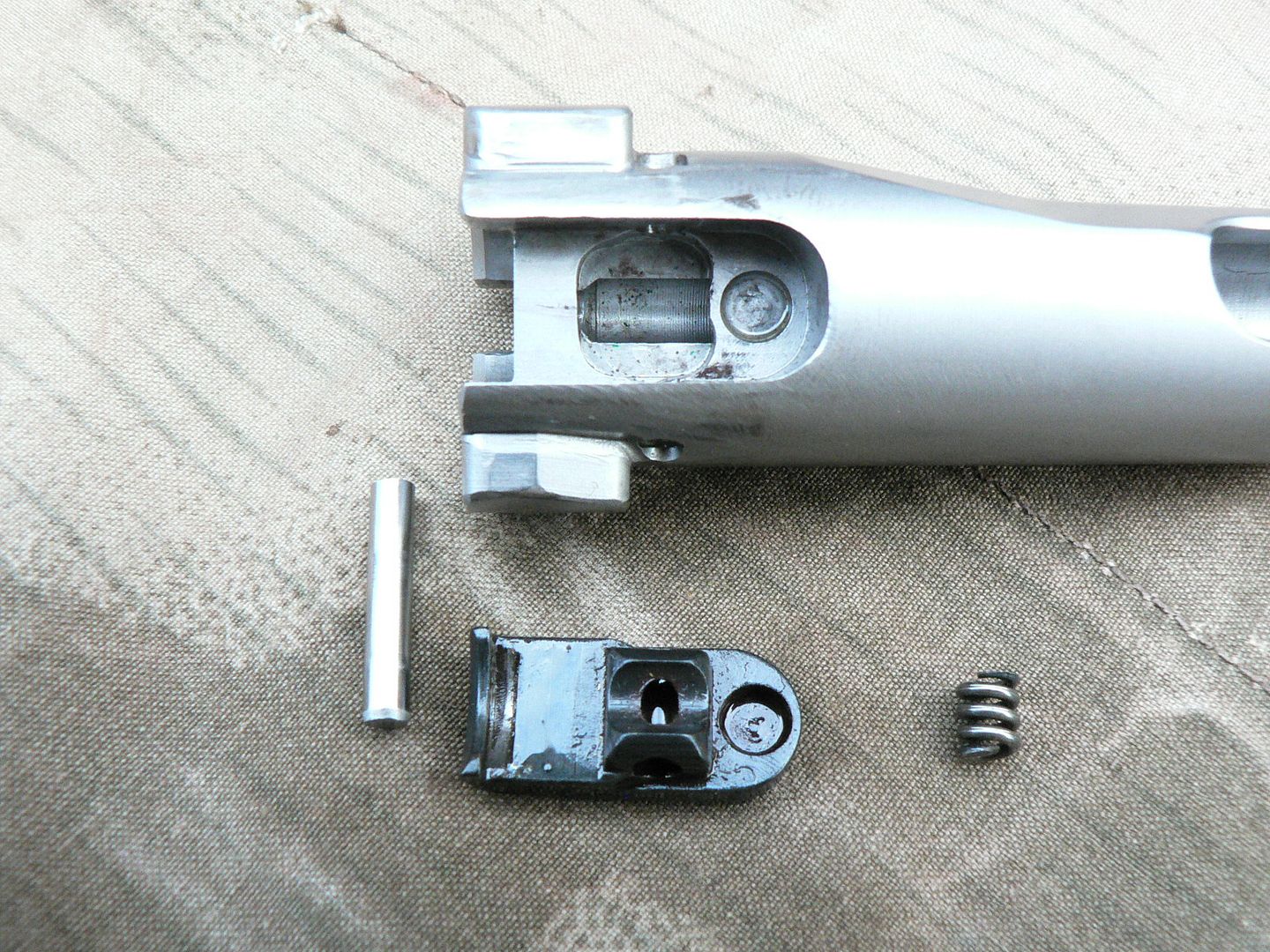

To disassemble, simply press down on the rear of the extractor and use a punch or bullet tip to push the retaining pin out. Here it is shown disassembled:

When reassembling the extractor, be careful that the spring engages the cutouts for it in both the bolt and extractor. It's small and can easily be tipped on its side during reassembly. This design is different than an original rifle but I don't know why. I do know that it works just fine. It also comes apart and goes back together very easily which is a big plus after messing with that cursed firing spring plunger earlier. Did mention that part needed to be redesigned?

That's it for the bolt. In the next post, we'll start with the bolt carrier and go from there. See you then!

Here are a couple photos of the cam slot showing what is again NORMAL wear:

SMG says in the video included with each rifle that you may even start to see chips of metal missing in this area over time. Apparently, it is normal so don't wig out when this starts to happen. Just keep shooting. SMG has over 15,000 rounds through their test rifle so I'll just take their word for it. I know I'll probably never put 15K through mine unless one of you want's to donate some ammo. I don't know what the black marks are in the wear area. It doesn't rub off so I just ignore it.

Let's take the extractor apart. Here it is assembled:

To disassemble, simply press down on the rear of the extractor and use a punch or bullet tip to push the retaining pin out. Here it is shown disassembled:

When reassembling the extractor, be careful that the spring engages the cutouts for it in both the bolt and extractor. It's small and can easily be tipped on its side during reassembly. This design is different than an original rifle but I don't know why. I do know that it works just fine. It also comes apart and goes back together very easily which is a big plus after messing with that cursed firing spring plunger earlier. Did mention that part needed to be redesigned?

That's it for the bolt. In the next post, we'll start with the bolt carrier and go from there. See you then!

I run the weapon somewhat wet and probably use waaaay too much lubrication, but it has always seemed to help in any new SAs I've bought during any break in period - unlike my 1989 Chinese AK which didn't need any break-in period *(see below). The over lubing helps with my PTR44 too.

I run the weapon somewhat wet and probably use waaaay too much lubrication, but it has always seemed to help in any new SAs I've bought during any break in period - unlike my 1989 Chinese AK which didn't need any break-in period *(see below). The over lubing helps with my PTR44 too.