mauser1908

Senior Member

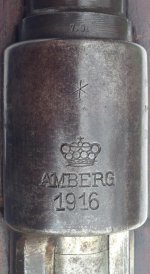

Pieper was a well known subcontractor that manufactured parts for both the Gew 98 and Lugers. It's well documented they made receivers for Spandau identified by Crown J hardening proof. Erfurt used them to make side plates during 1917 and 1918, these are also identified by the same Crown J.

On my rifle, I noticed there are Crown Js on the Buttplate, magazine, both barrel bands, and bayonet lug. To me this would indicate these parts were made by Pieper in Liege. In addition, the floorplate and follower were made by a different subcontractor.

The first magazine shown is from a 'cc' block 1917/18 WMO, assembled Spandau, the manufacturer acceptance is a Crown J. In addition this magazine also uses a floorplate and follower from the same subcontractor as mine. I have read over the years that these WMO Spandaus were effectively Sterngewehrs. I think a good objective of this study would be to determine the scope of WMO's sterngewehr program. Much like Danzig sterngewehrs, these WMO assembled Spandaus were just rolled into standard production. It may be possible that this initiative encompassed standard WMO receivers in the same way the other Sterngewehr manufactures used their own. Without a receiver from a different manufacturer or the WMO hallmark these would be next to impossible to identify outside of where they sourced their parts.

1. WMO assembled Spandau 'cc' block 1917/18

2. Magazine, floorplate, and follower from WMO 1917 43aa

3. Buttplate, barrel bands, and bayonet lug.

I very well could be totally off on this, I just thought I would throw the idea out there. In my thought process, this would be the same inspector as the J is not underscored which would indicate a different individual who's last name also started with a J.

On my rifle, I noticed there are Crown Js on the Buttplate, magazine, both barrel bands, and bayonet lug. To me this would indicate these parts were made by Pieper in Liege. In addition, the floorplate and follower were made by a different subcontractor.

The first magazine shown is from a 'cc' block 1917/18 WMO, assembled Spandau, the manufacturer acceptance is a Crown J. In addition this magazine also uses a floorplate and follower from the same subcontractor as mine. I have read over the years that these WMO Spandaus were effectively Sterngewehrs. I think a good objective of this study would be to determine the scope of WMO's sterngewehr program. Much like Danzig sterngewehrs, these WMO assembled Spandaus were just rolled into standard production. It may be possible that this initiative encompassed standard WMO receivers in the same way the other Sterngewehr manufactures used their own. Without a receiver from a different manufacturer or the WMO hallmark these would be next to impossible to identify outside of where they sourced their parts.

1. WMO assembled Spandau 'cc' block 1917/18

2. Magazine, floorplate, and follower from WMO 1917 43aa

3. Buttplate, barrel bands, and bayonet lug.

I very well could be totally off on this, I just thought I would throw the idea out there. In my thought process, this would be the same inspector as the J is not underscored which would indicate a different individual who's last name also started with a J.

Last edited: