You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BSW not a turd apparently, at Oaks Pa gun show

- Thread starter mauser202

- Start date

heavy_mech

RKI- Reasonably Knowledgable Individual

I wonder if the barrel code can provide a clue as to when these were assembled. I see in the KCN datasheet it's 40 Ru 95 and in the OP rifle it's 40 Ru 125. I can't see it in the photos from the auction, but I wonder if Nulle was the winner and whether he still has this?

So looking in the bible it appears that "by the b block of 1942, the barrel serial number had been eliminated". The OP doesn't show that photo, but the 2 examples Loewe shared both have the barrel serial which would lead me to believe these were assembled before 1942.

Looking at reported barrel codes, 40 Ru 4 was used on 4448b and 40 Ru 133 appears on 4175f in 1940, so it would seem that lot #s 95 and 125 could certainly be in the d block of 1940 production. I think that exact barrel code pattern might be important in dating these.

So looking in the bible it appears that "by the b block of 1942, the barrel serial number had been eliminated". The OP doesn't show that photo, but the 2 examples Loewe shared both have the barrel serial which would lead me to believe these were assembled before 1942.

Looking at reported barrel codes, 40 Ru 4 was used on 4448b and 40 Ru 133 appears on 4175f in 1940, so it would seem that lot #s 95 and 125 could certainly be in the d block of 1940 production. I think that exact barrel code pattern might be important in dating these.

Last edited:

Stephan98k

aka 8x57IS

Paul, thank you very much for your contributions and the photos, they are very important. I will do my best to answer all the other questions as soon as possible.

I already wrote the following in my first post and this part is extremely important and necessary to understand everything else, therefore I will quote myself:

"The Gustloff K98k assembly did not run continuously and was interrupted in 1940 and 1941. The reason is the redirection of armaments through an order from July 13, 1940 by Adolf Hitler. In June 1941 the armament was again redirected to the detriment of the K98k - which was also one of the reasons that led to the so-called "Rifle Crisis" in 1941/1942. Many of the "bcd41" coded K98k were assembled in 1942 after a longer interruption."

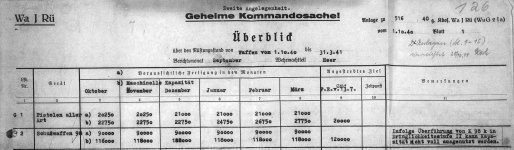

The assembly of K98k rifles in Weimar at the Fritz-Sauckel-Werk should begin at the end of the year 1939 but due to start-up difficulties and other troubles only a few K98k were assembled in 1939. Most of the "337 1939" coded K98k rifles got assembled early in the year 1940. Here are excerpts from two relevant documents:

The document shown above states the following: "Discontinuation of all companies that manufacture carbines, with the exception of two companies that are starting up (Sachsengruppe and Steyr)."

The second Waffenamt document is from January 15, 1940 and on the right side under "notes" about the K98k is written:

"Regarding columns 4 and 8:

Lack of workers at Mauser, start-up difficulties at Sachsengruppe (Saxonia Group), assembly difficulties at Steyr. In addition, 2,000 pieces have been manufactured for Kriegsmarine."

Another example is the weather conditions in the winter of 1940 and here is a short excerpt from a multi-page document "Overview of the industrial armaments situation in the Heer - Completed March 15, 1940":

"I. Manufacturing:

The entire production in February 1940 was under the impression of the unusual cold period with all the accompanying effects (shutdowns due to a lack of coal, electricity and gas, transport closures, etc.)

Weapons and equipment:

Overall, the production level of the previous month was maintained despite the effects of the cold period. Manufacturing capacity cannot be fully utilized even for main weapons and even for Führer-demands due to a shortage of workers and slow supply of raw materials (for bar steel and sheet metal, delivery times are still 6 to 9 months!). For the same reasons, a significant increase in production can only be expected in the following months if these difficulties, which are controlled by the OKH, are resolved. In many companies there is already a buildup of half-finished weapons that cannot be further processed and assembled because individual parts are missing. In the case of weapons (including Führer-demands), production was also affected by the fact that, according to the OKW order of February 9th, weapons production was no longer classified as priority level I and therefore all the advantages of being classified as priority level I (priority to get workers, machines and steel supplies) were automatically no longer applicable.

Following OKH's objection, "Continued production of weapons" and "Equipping the fast troops" were again set to priority level I. Production losses that have occurred in the meantime cannot be recovered and will continue to have an impact on short deliveries in the following months. Due to the high need for new troop formations, serious shortages have also arisen in many non-major weapons. However, there are almost no raw materials available to manufacture these weapons."

Always keep in mind, at this time and even in 1941 and 1942, the Fritz-Sauckel-Werk in Weimar was still under construction, this circumstance and further problems hindered K98k assembly.

In the sentence quoted from my first post I had already mentioned the redirection of armaments through an order from July 13, 1940 by Adolf Hitler.

Below is a document from the Army General Staff dated June 5, 1940. This document deals with the weapon losses in the Western campaign calculated on a monthly average compared to the monthly production of the weapons mentioned.

Due to the high front consumption of the other weapons compared to the K98k in the Western campaign, the armament was redirected, it had become necessary. The monthly average loss of rifles is 10,000 pieces and in the comparable month of April 1940, according to this WaA information, 94,000 rifles was manufactured.

(A side note on April 1940 and the K98k numbers. Although 94,000 rifles was manufactured for the Army, according to the official list the Army only received around 84,000 K98k. This difference is K98k taken from H.Za inventories for export to Sweden in April 1940. This delivery included K98k from the manufacturers Mauser Berlin, Sauer & Sohn and Gustloff-Werke.)

The losses of rifles were small in comparison and could be replaced in only about 4 days of production time. With the other weapons such as the 3.7cm anti-tank gun, the situation was different, 500 of them were destroyed in the month but only 327 were manufactured, which was a catastrophic development that had to be counteracted.

The K98k production was transferred to priority level II and therefore there was a lack of materials and workers - the assembly of K98k stalled again.

Similar to what happened in early 1940 with the "337 1939" coded K98ks, many of the "337 1940" coded K98k rifles were also assembled later, in 1941, and this causes some confusion, as example in the production totals for the respective years. The document shown above states the following:

"As a result of K98k being transferred to priority level II, capacity cannot be fully utilized."

But also in 1941 there was no continuous K98k assembly in Weimar because the armament was again redirected, this time it was the Führerbefehl (Adolf Hitler directive) No. 32 from June 11, 1941.

The Waffenamt document of June 27, 1941 has the subject "Redirection of Heer armament" and the appendix to this document is entitled "Restriction of production a) Weapons and equipment".

Production according to the Heer production program was 100,000 K98k per month and it is proposed to reduce the number to 55,000 K98k per month from October 1, 1941.

Due to the redirection of armaments production and a shortage of workers, assembly of the K98k at the Fritz-Sauckel-Werk in Weimar was stopped in 1941. Here is an excerpt from the book "Die Inzenierung der Stadt Weimar - Planen und Bauen im Nationalsozialismus in Weimar" by Karina Loos about this topic:

"In 1940, the Fritz-Sauckel-Werk received a wartime contract directly from the Oberkommando der Wehrmacht (High Command of the Armed Forces) to produce K98k carbines, and in 1941 it also received an order to build a production facility to manufacture 2cm-Flak 38 including accessories and spare parts, which was intended to be financed by the Oberkommando der Wehrmacht.

Due to the shortage of workers, the “Waffenschmiede” (Armory) of the Gau capital Weimar, the “Fritz-Sauckel-Werk”, had stopped producing the 98k carbine. Due to the high increase in the need for weapons, resumption of production from February 1942 was considered."

As already mentioned, the redirection of armaments production was the main reason for the shutdown of K98k assembly at the Fritz-Sauckel-Werk in 1941. There were many parts in stock because more K98k were supposed to be assembled, but due to the interruptions they were not immediately used in production and therefore many parts are not linear but mixed. In this context, I would like to remind you again of the sentence "In many companies there is already a buildup of half-finished weapons that cannot be further processed and assembled because individual parts are missing." from the document dated March 15, 1940.

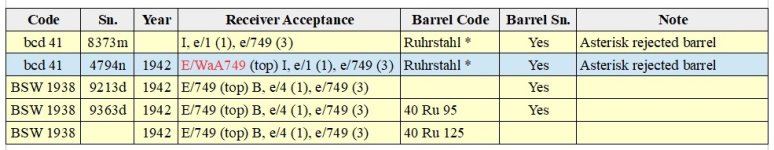

Please look at the diagram which I did with the K98k Waffenamt data.

The green bars represent the K98k Heer supplies, the blue ones with the letter "L" are Luftwaffe K98k and the third ones with the letter "M" are Kriegsmarine K98k. Each of the small boxes on the diagram corresponds to 2,500 K98k rifles. The division is a bit rough and therefore the small numbers had to be rounded a bit. We have the exact numbers, the diagram is only intended to visually show the effects of the Führerbefehl (Adolf Hitler directive) No. 32 from June 11, 1941. There is a red mark in the diagram for June 1941 for better visibility.

As you can see in my diagram, another important reason for the emergence of the Rifle Crisis in 1941 / 1942 was the overreach and increased demands of Hermann Göring. The capacity from the Heer was redirected to the Luftwaffe. In case you are wondering why the first column representing April 1941 has four green bars with the letter "L" - there are several documents about this and one of these documents is shown in the K98k Volume II book in the Mauser Oberndorf chapter on page 124 and here is a short excerpt from the document:

"The 10,000 pieces, which could not be delivered during March 1941, have to be made up in April, so that a total of 20,000 carbines have to be delivered in April for the above order."

During this period Heer K98k was redirected to the Luftwaffe and the four green bars with the letter "L" in my diagram show these 10,000 Heer K98k which was delivered to the Luftzeugamt Küpper.

The Minister of Armaments Albert Speer complained to Adolf Hitler about this situation several times, as example at a Führer meeting on February 19, 1942:

"I pointed out to the Führer that air force production has continually increased in labor usage, while army production in labor usage has remained the same. At the same time it was pointed out that this was a consequence of the Reich Marshal's very frequent intervention in favor of the Luftwaffe."

Führer meeting on March 16, 1942:

"The Führer is still very upset about the lack of workers in weapons production. I reported on the Rheinmetall-Borsig night shift and at the same time presented the curve for the development of workers in the Luftwaffe and Heer. It was pointed out that the Heer was constantly at a slight disadvantage due to the powerful advance of the Luftwaffe. The Führer wants the appropriate number of workers to finally be allocated to weapons production and other Heer production."

Führer meeting on March 19, 1942:

"Number of workers in the Heer, Kriegsmarine, Luftwaffe was presented to the Führer and asked him to ask Göring to give up any influence to increase the Luftwaffe, since Heer production, in particular weapons, is given priority; a significant increase in the Heer must be achieved in March and the Luftwaffe must remain the same."

Shown below is an excerpt from an email I sent to a friend. The topic of my email is mainly Mauser Berlin, but the situation was similar and that's why I'm showing it. Also, it might be helpful to understand my diagram.

"Your ar41 Sn. 4840i is Heer and late production (with late I mean Mauser Berlin stopped K98k production in 1941 and resumed in 1942. Keep in mind it was similar with Gustloff Werke.).

As already said, the increasing number of Luftwaffe K98k's appearing in my serial number study from the middle "c" block is clearly visible and it is also reflected in the documents. In the Waffenamt document for April 1941 is written: The Luftwaffe demand of 20,000 K98k is increased to 30,000 K98k, these are at the expense of the Heer and even this already very high number was increased to 38,280 K98k upon delivery. The Kriegsmarine was very reserved and consistent with K98k deliveries. It was 2,000 K98k monthly and from July 1941 it was increased to 6,000 K98k. All these deliveries were at the expense of the Heer and these were already perfect ingredients for the Rifle Crisis in 1941 /1942.

If you look at the distribution ratio of K98k in December 1941, you can clearly see the looming catastrophe for the Heer.

Heer 38,182 K98k (This number includes 4,572 K98k Zf.41) - Luftwaffe 24,300 K98k (This number includes 500 K98k Zf.41) - Kriegsmarine 8,000 K98k.

The Heer was actually supposed to receive 50,000 K98k in December 1941, but there was a loss of production due to the Christmas holidays.

The previous months were of course not without their effects. In April 1941, the Luftwaffe increased its demands and other weapons in production also ended during this period. In May 1941 there are the last 2,900 Kriegsmarine G.29/40 and also the last 90 Heer G.33/40 from the first order. In September 1941 there are the first 7,813 G.33/40 from the second order. There were actually supposed to be 10,000, but there were start-up and manufacturing difficulties."

I think it's good that I also used Mauser Berlin as an example. With this manufacturer you can clearly see the effects of delays and production stops. Actually production was supposed to be continuous and as a result there were many parts in stock. When production was stopped, these parts were stored and used in production with a delay. The question is often asked why Mauser Berlin still used stocks with a flat buttplate in 1942 - the answer is above.

To give you an idea of the low production - between January and June 1942 only 35,029 Mauser Berlin K98k rifles were accepted by the Waffenamt.

Another good example is the following question from thread "ZF41 Study":

www.k98kforum.com

"Hi

www.k98kforum.com

"Hi

Have you ever seen an ar K98 ZF41 with flat rail in the L block of 1942 ? If not , how do you explain cxn first type ZF41 with blue circle on original L block mount with flat rollers ? just a thought.

best regards"

Here is a screenshot of the conversation to make it easier to understand:

We have documents from the Zf41 Trials in February and March 1941. Even at this early date, before the official introduction of the K98k Zf41, something very interesting was noted in the document. The soldiers shouldn't mention problems with the mount (flat roller) because it was already noted in February 1941 to get changed when series production started. Maybe Bruce will show the document in the Addendum book.

If you ask yourself why the flat rollers were still used in 1942, this question is also answered with the explanations above.

Now enough with this "introduction", I hope it is understandable and you can follow me. These complex topics are very difficult for me to explain in English and it is very time consuming.

Regards,

Stephan

I already wrote the following in my first post and this part is extremely important and necessary to understand everything else, therefore I will quote myself:

"The Gustloff K98k assembly did not run continuously and was interrupted in 1940 and 1941. The reason is the redirection of armaments through an order from July 13, 1940 by Adolf Hitler. In June 1941 the armament was again redirected to the detriment of the K98k - which was also one of the reasons that led to the so-called "Rifle Crisis" in 1941/1942. Many of the "bcd41" coded K98k were assembled in 1942 after a longer interruption."

The assembly of K98k rifles in Weimar at the Fritz-Sauckel-Werk should begin at the end of the year 1939 but due to start-up difficulties and other troubles only a few K98k were assembled in 1939. Most of the "337 1939" coded K98k rifles got assembled early in the year 1940. Here are excerpts from two relevant documents:

The document shown above states the following: "Discontinuation of all companies that manufacture carbines, with the exception of two companies that are starting up (Sachsengruppe and Steyr)."

The second Waffenamt document is from January 15, 1940 and on the right side under "notes" about the K98k is written:

"Regarding columns 4 and 8:

Lack of workers at Mauser, start-up difficulties at Sachsengruppe (Saxonia Group), assembly difficulties at Steyr. In addition, 2,000 pieces have been manufactured for Kriegsmarine."

Another example is the weather conditions in the winter of 1940 and here is a short excerpt from a multi-page document "Overview of the industrial armaments situation in the Heer - Completed March 15, 1940":

"I. Manufacturing:

The entire production in February 1940 was under the impression of the unusual cold period with all the accompanying effects (shutdowns due to a lack of coal, electricity and gas, transport closures, etc.)

Weapons and equipment:

Overall, the production level of the previous month was maintained despite the effects of the cold period. Manufacturing capacity cannot be fully utilized even for main weapons and even for Führer-demands due to a shortage of workers and slow supply of raw materials (for bar steel and sheet metal, delivery times are still 6 to 9 months!). For the same reasons, a significant increase in production can only be expected in the following months if these difficulties, which are controlled by the OKH, are resolved. In many companies there is already a buildup of half-finished weapons that cannot be further processed and assembled because individual parts are missing. In the case of weapons (including Führer-demands), production was also affected by the fact that, according to the OKW order of February 9th, weapons production was no longer classified as priority level I and therefore all the advantages of being classified as priority level I (priority to get workers, machines and steel supplies) were automatically no longer applicable.

Following OKH's objection, "Continued production of weapons" and "Equipping the fast troops" were again set to priority level I. Production losses that have occurred in the meantime cannot be recovered and will continue to have an impact on short deliveries in the following months. Due to the high need for new troop formations, serious shortages have also arisen in many non-major weapons. However, there are almost no raw materials available to manufacture these weapons."

Always keep in mind, at this time and even in 1941 and 1942, the Fritz-Sauckel-Werk in Weimar was still under construction, this circumstance and further problems hindered K98k assembly.

In the sentence quoted from my first post I had already mentioned the redirection of armaments through an order from July 13, 1940 by Adolf Hitler.

Below is a document from the Army General Staff dated June 5, 1940. This document deals with the weapon losses in the Western campaign calculated on a monthly average compared to the monthly production of the weapons mentioned.

Due to the high front consumption of the other weapons compared to the K98k in the Western campaign, the armament was redirected, it had become necessary. The monthly average loss of rifles is 10,000 pieces and in the comparable month of April 1940, according to this WaA information, 94,000 rifles was manufactured.

(A side note on April 1940 and the K98k numbers. Although 94,000 rifles was manufactured for the Army, according to the official list the Army only received around 84,000 K98k. This difference is K98k taken from H.Za inventories for export to Sweden in April 1940. This delivery included K98k from the manufacturers Mauser Berlin, Sauer & Sohn and Gustloff-Werke.)

The losses of rifles were small in comparison and could be replaced in only about 4 days of production time. With the other weapons such as the 3.7cm anti-tank gun, the situation was different, 500 of them were destroyed in the month but only 327 were manufactured, which was a catastrophic development that had to be counteracted.

The K98k production was transferred to priority level II and therefore there was a lack of materials and workers - the assembly of K98k stalled again.

Similar to what happened in early 1940 with the "337 1939" coded K98ks, many of the "337 1940" coded K98k rifles were also assembled later, in 1941, and this causes some confusion, as example in the production totals for the respective years. The document shown above states the following:

"As a result of K98k being transferred to priority level II, capacity cannot be fully utilized."

But also in 1941 there was no continuous K98k assembly in Weimar because the armament was again redirected, this time it was the Führerbefehl (Adolf Hitler directive) No. 32 from June 11, 1941.

The Waffenamt document of June 27, 1941 has the subject "Redirection of Heer armament" and the appendix to this document is entitled "Restriction of production a) Weapons and equipment".

Production according to the Heer production program was 100,000 K98k per month and it is proposed to reduce the number to 55,000 K98k per month from October 1, 1941.

Due to the redirection of armaments production and a shortage of workers, assembly of the K98k at the Fritz-Sauckel-Werk in Weimar was stopped in 1941. Here is an excerpt from the book "Die Inzenierung der Stadt Weimar - Planen und Bauen im Nationalsozialismus in Weimar" by Karina Loos about this topic:

"In 1940, the Fritz-Sauckel-Werk received a wartime contract directly from the Oberkommando der Wehrmacht (High Command of the Armed Forces) to produce K98k carbines, and in 1941 it also received an order to build a production facility to manufacture 2cm-Flak 38 including accessories and spare parts, which was intended to be financed by the Oberkommando der Wehrmacht.

Due to the shortage of workers, the “Waffenschmiede” (Armory) of the Gau capital Weimar, the “Fritz-Sauckel-Werk”, had stopped producing the 98k carbine. Due to the high increase in the need for weapons, resumption of production from February 1942 was considered."

As already mentioned, the redirection of armaments production was the main reason for the shutdown of K98k assembly at the Fritz-Sauckel-Werk in 1941. There were many parts in stock because more K98k were supposed to be assembled, but due to the interruptions they were not immediately used in production and therefore many parts are not linear but mixed. In this context, I would like to remind you again of the sentence "In many companies there is already a buildup of half-finished weapons that cannot be further processed and assembled because individual parts are missing." from the document dated March 15, 1940.

Please look at the diagram which I did with the K98k Waffenamt data.

The green bars represent the K98k Heer supplies, the blue ones with the letter "L" are Luftwaffe K98k and the third ones with the letter "M" are Kriegsmarine K98k. Each of the small boxes on the diagram corresponds to 2,500 K98k rifles. The division is a bit rough and therefore the small numbers had to be rounded a bit. We have the exact numbers, the diagram is only intended to visually show the effects of the Führerbefehl (Adolf Hitler directive) No. 32 from June 11, 1941. There is a red mark in the diagram for June 1941 for better visibility.

As you can see in my diagram, another important reason for the emergence of the Rifle Crisis in 1941 / 1942 was the overreach and increased demands of Hermann Göring. The capacity from the Heer was redirected to the Luftwaffe. In case you are wondering why the first column representing April 1941 has four green bars with the letter "L" - there are several documents about this and one of these documents is shown in the K98k Volume II book in the Mauser Oberndorf chapter on page 124 and here is a short excerpt from the document:

"The 10,000 pieces, which could not be delivered during March 1941, have to be made up in April, so that a total of 20,000 carbines have to be delivered in April for the above order."

During this period Heer K98k was redirected to the Luftwaffe and the four green bars with the letter "L" in my diagram show these 10,000 Heer K98k which was delivered to the Luftzeugamt Küpper.

The Minister of Armaments Albert Speer complained to Adolf Hitler about this situation several times, as example at a Führer meeting on February 19, 1942:

"I pointed out to the Führer that air force production has continually increased in labor usage, while army production in labor usage has remained the same. At the same time it was pointed out that this was a consequence of the Reich Marshal's very frequent intervention in favor of the Luftwaffe."

Führer meeting on March 16, 1942:

"The Führer is still very upset about the lack of workers in weapons production. I reported on the Rheinmetall-Borsig night shift and at the same time presented the curve for the development of workers in the Luftwaffe and Heer. It was pointed out that the Heer was constantly at a slight disadvantage due to the powerful advance of the Luftwaffe. The Führer wants the appropriate number of workers to finally be allocated to weapons production and other Heer production."

Führer meeting on March 19, 1942:

"Number of workers in the Heer, Kriegsmarine, Luftwaffe was presented to the Führer and asked him to ask Göring to give up any influence to increase the Luftwaffe, since Heer production, in particular weapons, is given priority; a significant increase in the Heer must be achieved in March and the Luftwaffe must remain the same."

Shown below is an excerpt from an email I sent to a friend. The topic of my email is mainly Mauser Berlin, but the situation was similar and that's why I'm showing it. Also, it might be helpful to understand my diagram.

"Your ar41 Sn. 4840i is Heer and late production (with late I mean Mauser Berlin stopped K98k production in 1941 and resumed in 1942. Keep in mind it was similar with Gustloff Werke.).

As already said, the increasing number of Luftwaffe K98k's appearing in my serial number study from the middle "c" block is clearly visible and it is also reflected in the documents. In the Waffenamt document for April 1941 is written: The Luftwaffe demand of 20,000 K98k is increased to 30,000 K98k, these are at the expense of the Heer and even this already very high number was increased to 38,280 K98k upon delivery. The Kriegsmarine was very reserved and consistent with K98k deliveries. It was 2,000 K98k monthly and from July 1941 it was increased to 6,000 K98k. All these deliveries were at the expense of the Heer and these were already perfect ingredients for the Rifle Crisis in 1941 /1942.

If you look at the distribution ratio of K98k in December 1941, you can clearly see the looming catastrophe for the Heer.

Heer 38,182 K98k (This number includes 4,572 K98k Zf.41) - Luftwaffe 24,300 K98k (This number includes 500 K98k Zf.41) - Kriegsmarine 8,000 K98k.

The Heer was actually supposed to receive 50,000 K98k in December 1941, but there was a loss of production due to the Christmas holidays.

The previous months were of course not without their effects. In April 1941, the Luftwaffe increased its demands and other weapons in production also ended during this period. In May 1941 there are the last 2,900 Kriegsmarine G.29/40 and also the last 90 Heer G.33/40 from the first order. In September 1941 there are the first 7,813 G.33/40 from the second order. There were actually supposed to be 10,000, but there were start-up and manufacturing difficulties."

I think it's good that I also used Mauser Berlin as an example. With this manufacturer you can clearly see the effects of delays and production stops. Actually production was supposed to be continuous and as a result there were many parts in stock. When production was stopped, these parts were stored and used in production with a delay. The question is often asked why Mauser Berlin still used stocks with a flat buttplate in 1942 - the answer is above.

To give you an idea of the low production - between January and June 1942 only 35,029 Mauser Berlin K98k rifles were accepted by the Waffenamt.

Another good example is the following question from thread "ZF41 Study":

ZF41 Study

Hi all, this is my first time to post a thread in this forum. I had been studying especially on ZF41 scopes. My website: http://zielfernrohr.b.la9.jp/index.htm And had been collecting data of them (serial# and markings) and compiling them into a list. After working on for about 10 years, now I...

Have you ever seen an ar K98 ZF41 with flat rail in the L block of 1942 ? If not , how do you explain cxn first type ZF41 with blue circle on original L block mount with flat rollers ? just a thought.

best regards"

Here is a screenshot of the conversation to make it easier to understand:

We have documents from the Zf41 Trials in February and March 1941. Even at this early date, before the official introduction of the K98k Zf41, something very interesting was noted in the document. The soldiers shouldn't mention problems with the mount (flat roller) because it was already noted in February 1941 to get changed when series production started. Maybe Bruce will show the document in the Addendum book.

If you ask yourself why the flat rollers were still used in 1942, this question is also answered with the explanations above.

Now enough with this "introduction", I hope it is understandable and you can follow me. These complex topics are very difficult for me to explain in English and it is very time consuming.

Regards,

Stephan

Paul, thank you very much for your contributions and the photos, they are very important. I will do my best to answer all the other questions as soon as possible.

I already wrote the following in my first post and this part is extremely important and necessary to understand everything else, therefore I will quote myself:

"The Gustloff K98k assembly did not run continuously and was interrupted in 1940 and 1941. The reason is the redirection of armaments through an order from July 13, 1940 by Adolf Hitler. In June 1941 the armament was again redirected to the detriment of the K98k - which was also one of the reasons that led to the so-called "Rifle Crisis" in 1941/1942. Many of the "bcd41" coded K98k were assembled in 1942 after a longer interruption."

The assembly of K98k rifles in Weimar at the Fritz-Sauckel-Werk should begin at the end of the year 1939 but due to start-up difficulties and other troubles only a few K98k were assembled in 1939. Most of the "337 1939" coded K98k rifles got assembled early in the year 1940. Here are excerpts from two relevant documents:

View attachment 383643

The document shown above states the following: "Discontinuation of all companies that manufacture carbines, with the exception of two companies that are starting up (Sachsengruppe and Steyr)."

View attachment 383644

The second Waffenamt document is from January 15, 1940 and on the right side under "notes" about the K98k is written:

"Regarding columns 4 and 8:

Lack of workers at Mauser, start-up difficulties at Sachsengruppe (Saxonia Group), assembly difficulties at Steyr. In addition, 2,000 pieces have been manufactured for Kriegsmarine."

Another example is the weather conditions in the winter of 1940 and here is a short excerpt from a multi-page document "Overview of the industrial armaments situation in the Heer - Completed March 15, 1940":

"I. Manufacturing:

The entire production in February 1940 was under the impression of the unusual cold period with all the accompanying effects (shutdowns due to a lack of coal, electricity and gas, transport closures, etc.)

Weapons and equipment:

Overall, the production level of the previous month was maintained despite the effects of the cold period. Manufacturing capacity cannot be fully utilized even for main weapons and even for Führer-demands due to a shortage of workers and slow supply of raw materials (for bar steel and sheet metal, delivery times are still 6 to 9 months!). For the same reasons, a significant increase in production can only be expected in the following months if these difficulties, which are controlled by the OKH, are resolved. In many companies there is already a buildup of half-finished weapons that cannot be further processed and assembled because individual parts are missing. In the case of weapons (including Führer-demands), production was also affected by the fact that, according to the OKW order of February 9th, weapons production was no longer classified as priority level I and therefore all the advantages of being classified as priority level I (priority to get workers, machines and steel supplies) were automatically no longer applicable.

Following OKH's objection, "Continued production of weapons" and "Equipping the fast troops" were again set to priority level I. Production losses that have occurred in the meantime cannot be recovered and will continue to have an impact on short deliveries in the following months. Due to the high need for new troop formations, serious shortages have also arisen in many non-major weapons. However, there are almost no raw materials available to manufacture these weapons."

Always keep in mind, at this time and even in 1941 and 1942, the Fritz-Sauckel-Werk in Weimar was still under construction, this circumstance and further problems hindered K98k assembly.

In the sentence quoted from my first post I had already mentioned the redirection of armaments through an order from July 13, 1940 by Adolf Hitler.

Below is a document from the Army General Staff dated June 5, 1940. This document deals with the weapon losses in the Western campaign calculated on a monthly average compared to the monthly production of the weapons mentioned.

View attachment 383645

Due to the high front consumption of the other weapons compared to the K98k in the Western campaign, the armament was redirected, it had become necessary. The monthly average loss of rifles is 10,000 pieces and in the comparable month of April 1940, according to this WaA information, 94,000 rifles was manufactured.

(A side note on April 1940 and the K98k numbers. Although 94,000 rifles was manufactured for the Army, according to the official list the Army only received around 84,000 K98k. This difference is K98k taken from H.Za inventories for export to Sweden in April 1940. This delivery included K98k from the manufacturers Mauser Berlin, Sauer & Sohn and Gustloff-Werke.)

The losses of rifles were small in comparison and could be replaced in only about 4 days of production time. With the other weapons such as the 3.7cm anti-tank gun, the situation was different, 500 of them were destroyed in the month but only 327 were manufactured, which was a catastrophic development that had to be counteracted.

The K98k production was transferred to priority level II and therefore there was a lack of materials and workers - the assembly of K98k stalled again.

View attachment 383646

Similar to what happened in early 1940 with the "337 1939" coded K98ks, many of the "337 1940" coded K98k rifles were also assembled later, in 1941, and this causes some confusion, as example in the production totals for the respective years. The document shown above states the following:

"As a result of K98k being transferred to priority level II, capacity cannot be fully utilized."

But also in 1941 there was no continuous K98k assembly in Weimar because the armament was again redirected, this time it was the Führerbefehl (Adolf Hitler directive) No. 32 from June 11, 1941.

View attachment 383647

View attachment 383648

The Waffenamt document of June 27, 1941 has the subject "Redirection of Heer armament" and the appendix to this document is entitled "Restriction of production a) Weapons and equipment".

Production according to the Heer production program was 100,000 K98k per month and it is proposed to reduce the number to 55,000 K98k per month from October 1, 1941.

Due to the redirection of armaments production and a shortage of workers, assembly of the K98k at the Fritz-Sauckel-Werk in Weimar was stopped in 1941. Here is an excerpt from the book "Die Inzenierung der Stadt Weimar - Planen und Bauen im Nationalsozialismus in Weimar" by Karina Loos about this topic:

"In 1940, the Fritz-Sauckel-Werk received a wartime contract directly from the Oberkommando der Wehrmacht (High Command of the Armed Forces) to produce K98k carbines, and in 1941 it also received an order to build a production facility to manufacture 2cm-Flak 38 including accessories and spare parts, which was intended to be financed by the Oberkommando der Wehrmacht.

Due to the shortage of workers, the “Waffenschmiede” (Armory) of the Gau capital Weimar, the “Fritz-Sauckel-Werk”, had stopped producing the 98k carbine. Due to the high increase in the need for weapons, resumption of production from February 1942 was considered."

As already mentioned, the redirection of armaments production was the main reason for the shutdown of K98k assembly at the Fritz-Sauckel-Werk in 1941. There were many parts in stock because more K98k were supposed to be assembled, but due to the interruptions they were not immediately used in production and therefore many parts are not linear but mixed. In this context, I would like to remind you again of the sentence "In many companies there is already a buildup of half-finished weapons that cannot be further processed and assembled because individual parts are missing." from the document dated March 15, 1940.

View attachment 383649

Please look at the diagram which I did with the K98k Waffenamt data.

The green bars represent the K98k Heer supplies, the blue ones with the letter "L" are Luftwaffe K98k and the third ones with the letter "M" are Kriegsmarine K98k. Each of the small boxes on the diagram corresponds to 2,500 K98k rifles. The division is a bit rough and therefore the small numbers had to be rounded a bit. We have the exact numbers, the diagram is only intended to visually show the effects of the Führerbefehl (Adolf Hitler directive) No. 32 from June 11, 1941. There is a red mark in the diagram for June 1941 for better visibility.

As you can see in my diagram, another important reason for the emergence of the Rifle Crisis in 1941 / 1942 was the overreach and increased demands of Hermann Göring. The capacity from the Heer was redirected to the Luftwaffe. In case you are wondering why the first column representing April 1941 has four green bars with the letter "L" - there are several documents about this and one of these documents is shown in the K98k Volume II book in the Mauser Oberndorf chapter on page 124 and here is a short excerpt from the document:

"The 10,000 pieces, which could not be delivered during March 1941, have to be made up in April, so that a total of 20,000 carbines have to be delivered in April for the above order."

During this period Heer K98k was redirected to the Luftwaffe and the four green bars with the letter "L" in my diagram show these 10,000 Heer K98k which was delivered to the Luftzeugamt Küpper.

The Minister of Armaments Albert Speer complained to Adolf Hitler about this situation several times, as example at a Führer meeting on February 19, 1942:

"I pointed out to the Führer that air force production has continually increased in labor usage, while army production in labor usage has remained the same. At the same time it was pointed out that this was a consequence of the Reich Marshal's very frequent intervention in favor of the Luftwaffe."

Führer meeting on March 16, 1942:

"The Führer is still very upset about the lack of workers in weapons production. I reported on the Rheinmetall-Borsig night shift and at the same time presented the curve for the development of workers in the Luftwaffe and Heer. It was pointed out that the Heer was constantly at a slight disadvantage due to the powerful advance of the Luftwaffe. The Führer wants the appropriate number of workers to finally be allocated to weapons production and other Heer production."

Führer meeting on March 19, 1942:

"Number of workers in the Heer, Kriegsmarine, Luftwaffe was presented to the Führer and asked him to ask Göring to give up any influence to increase the Luftwaffe, since Heer production, in particular weapons, is given priority; a significant increase in the Heer must be achieved in March and the Luftwaffe must remain the same."

Shown below is an excerpt from an email I sent to a friend. The topic of my email is mainly Mauser Berlin, but the situation was similar and that's why I'm showing it. Also, it might be helpful to understand my diagram.

"Your ar41 Sn. 4840i is Heer and late production (with late I mean Mauser Berlin stopped K98k production in 1941 and resumed in 1942. Keep in mind it was similar with Gustloff Werke.).

As already said, the increasing number of Luftwaffe K98k's appearing in my serial number study from the middle "c" block is clearly visible and it is also reflected in the documents. In the Waffenamt document for April 1941 is written: The Luftwaffe demand of 20,000 K98k is increased to 30,000 K98k, these are at the expense of the Heer and even this already very high number was increased to 38,280 K98k upon delivery. The Kriegsmarine was very reserved and consistent with K98k deliveries. It was 2,000 K98k monthly and from July 1941 it was increased to 6,000 K98k. All these deliveries were at the expense of the Heer and these were already perfect ingredients for the Rifle Crisis in 1941 /1942.

If you look at the distribution ratio of K98k in December 1941, you can clearly see the looming catastrophe for the Heer.

Heer 38,182 K98k (This number includes 4,572 K98k Zf.41) - Luftwaffe 24,300 K98k (This number includes 500 K98k Zf.41) - Kriegsmarine 8,000 K98k.

The Heer was actually supposed to receive 50,000 K98k in December 1941, but there was a loss of production due to the Christmas holidays.

The previous months were of course not without their effects. In April 1941, the Luftwaffe increased its demands and other weapons in production also ended during this period. In May 1941 there are the last 2,900 Kriegsmarine G.29/40 and also the last 90 Heer G.33/40 from the first order. In September 1941 there are the first 7,813 G.33/40 from the second order. There were actually supposed to be 10,000, but there were start-up and manufacturing difficulties."

I think it's good that I also used Mauser Berlin as an example. With this manufacturer you can clearly see the effects of delays and production stops. Actually production was supposed to be continuous and as a result there were many parts in stock. When production was stopped, these parts were stored and used in production with a delay. The question is often asked why Mauser Berlin still used stocks with a flat buttplate in 1942 - the answer is above.

To give you an idea of the low production - between January and June 1942 only 35,029 Mauser Berlin K98k rifles were accepted by the Waffenamt.

Another good example is the following question from thread "ZF41 Study":

"Hi

ZF41 Study

Hi all, this is my first time to post a thread in this forum. I had been studying especially on ZF41 scopes. My website: http://zielfernrohr.b.la9.jp/index.htm And had been collecting data of them (serial# and markings) and compiling them into a list. After working on for about 10 years, now I...www.k98kforum.com

Have you ever seen an ar K98 ZF41 with flat rail in the L block of 1942 ? If not , how do you explain cxn first type ZF41 with blue circle on original L block mount with flat rollers ? just a thought.

best regards"

Here is a screenshot of the conversation to make it easier to understand:

View attachment 383652

We have documents from the Zf41 Trials in February and March 1941. Even at this early date, before the official introduction of the K98k Zf41, something very interesting was noted in the document. The soldiers shouldn't mention problems with the mount (flat roller) because it was already noted in February 1941 to get changed when series production started. Maybe Bruce will show the document in the Addendum book.

If you ask yourself why the flat rollers were still used in 1942, this question is also answered with the explanations above.

Now enough with this "introduction", I hope it is understandable and you can follow me. These complex topics are very difficult for me to explain in English and it is very time consuming.

Regards,

Stephan

Stephan, Your effort is understood and appreciated by most researchers who must have a reliance on the English language (such as any consistency in the english language exists... I can barely muddle through the UK variations and Australian, needless to say deal with India base customer service - one whom assured me she spoke the Queens English, whereupon I reminded her I wasn't the Queen of England); it amazes me the competency of yourself, Wolfgang and Bernd, especially in the nuance of translation. I suspect we (the english speaker) do not appreciate the difficulty involved, - Storz poor translation gives some idea to Imperialists, luckily his G88 and 71 books are far more professional in this regard.

My thoughts earlier, as to time frame, were derived from trends comparison, your outline shows the hazards of relying upon trends exclusively.

First class work was done here!

heavy_mech

RKI- Reasonably Knowledgable Individual

Thanks Stephan! That was a comprehensive and likely exhaustive response. Those period documents give some excellent context to your theories.

Guillaume d'Orange

Senior Member

Very interesting Stephan.Paul, thank you very much for your contributions and the photos, they are very important. I will do my best to answer all the other questions as soon as possible.

I already wrote the following in my first post and this part is extremely important and necessary to understand everything else, therefore I will quote myself:

"The Gustloff K98k assembly did not run continuously and was interrupted in 1940 and 1941. The reason is the redirection of armaments through an order from July 13, 1940 by Adolf Hitler. In June 1941 the armament was again redirected to the detriment of the K98k - which was also one of the reasons that led to the so-called "Rifle Crisis" in 1941/1942. Many of the "bcd41" coded K98k were assembled in 1942 after a longer interruption."

The assembly of K98k rifles in Weimar at the Fritz-Sauckel-Werk should begin at the end of the year 1939 but due to start-up difficulties and other troubles only a few K98k were assembled in 1939. Most of the "337 1939" coded K98k rifles got assembled early in the year 1940. Here are excerpts from two relevant documents:

View attachment 383643

The document shown above states the following: "Discontinuation of all companies that manufacture carbines, with the exception of two companies that are starting up (Sachsengruppe and Steyr)."

View attachment 383644

The second Waffenamt document is from January 15, 1940 and on the right side under "notes" about the K98k is written:

"Regarding columns 4 and 8:

Lack of workers at Mauser, start-up difficulties at Sachsengruppe (Saxonia Group), assembly difficulties at Steyr. In addition, 2,000 pieces have been manufactured for Kriegsmarine."

Another example is the weather conditions in the winter of 1940 and here is a short excerpt from a multi-page document "Overview of the industrial armaments situation in the Heer - Completed March 15, 1940":

"I. Manufacturing:

The entire production in February 1940 was under the impression of the unusual cold period with all the accompanying effects (shutdowns due to a lack of coal, electricity and gas, transport closures, etc.)

Weapons and equipment:

Overall, the production level of the previous month was maintained despite the effects of the cold period. Manufacturing capacity cannot be fully utilized even for main weapons and even for Führer-demands due to a shortage of workers and slow supply of raw materials (for bar steel and sheet metal, delivery times are still 6 to 9 months!). For the same reasons, a significant increase in production can only be expected in the following months if these difficulties, which are controlled by the OKH, are resolved. In many companies there is already a buildup of half-finished weapons that cannot be further processed and assembled because individual parts are missing. In the case of weapons (including Führer-demands), production was also affected by the fact that, according to the OKW order of February 9th, weapons production was no longer classified as priority level I and therefore all the advantages of being classified as priority level I (priority to get workers, machines and steel supplies) were automatically no longer applicable.

Following OKH's objection, "Continued production of weapons" and "Equipping the fast troops" were again set to priority level I. Production losses that have occurred in the meantime cannot be recovered and will continue to have an impact on short deliveries in the following months. Due to the high need for new troop formations, serious shortages have also arisen in many non-major weapons. However, there are almost no raw materials available to manufacture these weapons."

Always keep in mind, at this time and even in 1941 and 1942, the Fritz-Sauckel-Werk in Weimar was still under construction, this circumstance and further problems hindered K98k assembly.

In the sentence quoted from my first post I had already mentioned the redirection of armaments through an order from July 13, 1940 by Adolf Hitler.

Below is a document from the Army General Staff dated June 5, 1940. This document deals with the weapon losses in the Western campaign calculated on a monthly average compared to the monthly production of the weapons mentioned.

View attachment 383645

Due to the high front consumption of the other weapons compared to the K98k in the Western campaign, the armament was redirected, it had become necessary. The monthly average loss of rifles is 10,000 pieces and in the comparable month of April 1940, according to this WaA information, 94,000 rifles was manufactured.

(A side note on April 1940 and the K98k numbers. Although 94,000 rifles was manufactured for the Army, according to the official list the Army only received around 84,000 K98k. This difference is K98k taken from H.Za inventories for export to Sweden in April 1940. This delivery included K98k from the manufacturers Mauser Berlin, Sauer & Sohn and Gustloff-Werke.)

The losses of rifles were small in comparison and could be replaced in only about 4 days of production time. With the other weapons such as the 3.7cm anti-tank gun, the situation was different, 500 of them were destroyed in the month but only 327 were manufactured, which was a catastrophic development that had to be counteracted.

The K98k production was transferred to priority level II and therefore there was a lack of materials and workers - the assembly of K98k stalled again.

View attachment 383646

Similar to what happened in early 1940 with the "337 1939" coded K98ks, many of the "337 1940" coded K98k rifles were also assembled later, in 1941, and this causes some confusion, as example in the production totals for the respective years. The document shown above states the following:

"As a result of K98k being transferred to priority level II, capacity cannot be fully utilized."

But also in 1941 there was no continuous K98k assembly in Weimar because the armament was again redirected, this time it was the Führerbefehl (Adolf Hitler directive) No. 32 from June 11, 1941.

View attachment 383647

View attachment 383648

The Waffenamt document of June 27, 1941 has the subject "Redirection of Heer armament" and the appendix to this document is entitled "Restriction of production a) Weapons and equipment".

Production according to the Heer production program was 100,000 K98k per month and it is proposed to reduce the number to 55,000 K98k per month from October 1, 1941.

Due to the redirection of armaments production and a shortage of workers, assembly of the K98k at the Fritz-Sauckel-Werk in Weimar was stopped in 1941. Here is an excerpt from the book "Die Inzenierung der Stadt Weimar - Planen und Bauen im Nationalsozialismus in Weimar" by Karina Loos about this topic:

"In 1940, the Fritz-Sauckel-Werk received a wartime contract directly from the Oberkommando der Wehrmacht (High Command of the Armed Forces) to produce K98k carbines, and in 1941 it also received an order to build a production facility to manufacture 2cm-Flak 38 including accessories and spare parts, which was intended to be financed by the Oberkommando der Wehrmacht.

Due to the shortage of workers, the “Waffenschmiede” (Armory) of the Gau capital Weimar, the “Fritz-Sauckel-Werk”, had stopped producing the 98k carbine. Due to the high increase in the need for weapons, resumption of production from February 1942 was considered."

As already mentioned, the redirection of armaments production was the main reason for the shutdown of K98k assembly at the Fritz-Sauckel-Werk in 1941. There were many parts in stock because more K98k were supposed to be assembled, but due to the interruptions they were not immediately used in production and therefore many parts are not linear but mixed. In this context, I would like to remind you again of the sentence "In many companies there is already a buildup of half-finished weapons that cannot be further processed and assembled because individual parts are missing." from the document dated March 15, 1940.

View attachment 383649

Please look at the diagram which I did with the K98k Waffenamt data.

The green bars represent the K98k Heer supplies, the blue ones with the letter "L" are Luftwaffe K98k and the third ones with the letter "M" are Kriegsmarine K98k. Each of the small boxes on the diagram corresponds to 2,500 K98k rifles. The division is a bit rough and therefore the small numbers had to be rounded a bit. We have the exact numbers, the diagram is only intended to visually show the effects of the Führerbefehl (Adolf Hitler directive) No. 32 from June 11, 1941. There is a red mark in the diagram for June 1941 for better visibility.

As you can see in my diagram, another important reason for the emergence of the Rifle Crisis in 1941 / 1942 was the overreach and increased demands of Hermann Göring. The capacity from the Heer was redirected to the Luftwaffe. In case you are wondering why the first column representing April 1941 has four green bars with the letter "L" - there are several documents about this and one of these documents is shown in the K98k Volume II book in the Mauser Oberndorf chapter on page 124 and here is a short excerpt from the document:

"The 10,000 pieces, which could not be delivered during March 1941, have to be made up in April, so that a total of 20,000 carbines have to be delivered in April for the above order."

During this period Heer K98k was redirected to the Luftwaffe and the four green bars with the letter "L" in my diagram show these 10,000 Heer K98k which was delivered to the Luftzeugamt Küpper.

The Minister of Armaments Albert Speer complained to Adolf Hitler about this situation several times, as example at a Führer meeting on February 19, 1942:

"I pointed out to the Führer that air force production has continually increased in labor usage, while army production in labor usage has remained the same. At the same time it was pointed out that this was a consequence of the Reich Marshal's very frequent intervention in favor of the Luftwaffe."

Führer meeting on March 16, 1942:

"The Führer is still very upset about the lack of workers in weapons production. I reported on the Rheinmetall-Borsig night shift and at the same time presented the curve for the development of workers in the Luftwaffe and Heer. It was pointed out that the Heer was constantly at a slight disadvantage due to the powerful advance of the Luftwaffe. The Führer wants the appropriate number of workers to finally be allocated to weapons production and other Heer production."

Führer meeting on March 19, 1942:

"Number of workers in the Heer, Kriegsmarine, Luftwaffe was presented to the Führer and asked him to ask Göring to give up any influence to increase the Luftwaffe, since Heer production, in particular weapons, is given priority; a significant increase in the Heer must be achieved in March and the Luftwaffe must remain the same."

Shown below is an excerpt from an email I sent to a friend. The topic of my email is mainly Mauser Berlin, but the situation was similar and that's why I'm showing it. Also, it might be helpful to understand my diagram.

"Your ar41 Sn. 4840i is Heer and late production (with late I mean Mauser Berlin stopped K98k production in 1941 and resumed in 1942. Keep in mind it was similar with Gustloff Werke.).

As already said, the increasing number of Luftwaffe K98k's appearing in my serial number study from the middle "c" block is clearly visible and it is also reflected in the documents. In the Waffenamt document for April 1941 is written: The Luftwaffe demand of 20,000 K98k is increased to 30,000 K98k, these are at the expense of the Heer and even this already very high number was increased to 38,280 K98k upon delivery. The Kriegsmarine was very reserved and consistent with K98k deliveries. It was 2,000 K98k monthly and from July 1941 it was increased to 6,000 K98k. All these deliveries were at the expense of the Heer and these were already perfect ingredients for the Rifle Crisis in 1941 /1942.

If you look at the distribution ratio of K98k in December 1941, you can clearly see the looming catastrophe for the Heer.

Heer 38,182 K98k (This number includes 4,572 K98k Zf.41) - Luftwaffe 24,300 K98k (This number includes 500 K98k Zf.41) - Kriegsmarine 8,000 K98k.

The Heer was actually supposed to receive 50,000 K98k in December 1941, but there was a loss of production due to the Christmas holidays.

The previous months were of course not without their effects. In April 1941, the Luftwaffe increased its demands and other weapons in production also ended during this period. In May 1941 there are the last 2,900 Kriegsmarine G.29/40 and also the last 90 Heer G.33/40 from the first order. In September 1941 there are the first 7,813 G.33/40 from the second order. There were actually supposed to be 10,000, but there were start-up and manufacturing difficulties."

I think it's good that I also used Mauser Berlin as an example. With this manufacturer you can clearly see the effects of delays and production stops. Actually production was supposed to be continuous and as a result there were many parts in stock. When production was stopped, these parts were stored and used in production with a delay. The question is often asked why Mauser Berlin still used stocks with a flat buttplate in 1942 - the answer is above.

To give you an idea of the low production - between January and June 1942 only 35,029 Mauser Berlin K98k rifles were accepted by the Waffenamt.

Another good example is the following question from thread "ZF41 Study":

"Hi

ZF41 Study

Hi all, this is my first time to post a thread in this forum. I had been studying especially on ZF41 scopes. My website: http://zielfernrohr.b.la9.jp/index.htm And had been collecting data of them (serial# and markings) and compiling them into a list. After working on for about 10 years, now I...www.k98kforum.com

Have you ever seen an ar K98 ZF41 with flat rail in the L block of 1942 ? If not , how do you explain cxn first type ZF41 with blue circle on original L block mount with flat rollers ? just a thought.

best regards"

Here is a screenshot of the conversation to make it easier to understand:

View attachment 383652

We have documents from the Zf41 Trials in February and March 1941. Even at this early date, before the official introduction of the K98k Zf41, something very interesting was noted in the document. The soldiers shouldn't mention problems with the mount (flat roller) because it was already noted in February 1941 to get changed when series production started. Maybe Bruce will show the document in the Addendum book.

If you ask yourself why the flat rollers were still used in 1942, this question is also answered with the explanations above.

Now enough with this "introduction", I hope it is understandable and you can follow me. These complex topics are very difficult for me to explain in English and it is very time consuming.

Regards,

Stephan

This Befehl below may be a consequence of Weisung 32 that you were referring to. It redirects resources to Luftwaffe programs.

This is from « Führer Erlasse » edited by Martin Moll.

Weisung 32 can be found online. All the directives were edited by Walther Hubatsch.

Weisung 32 is referred to in a Befehl dated July 14 : "Richtlinien für die personelle und materielle Rüstung in Verbindung mit Weisung Nr. 32"

For the record, my translation of the rationalization decree (when AH understood he won't take Moscow):

Hitler's Rationalization Decree (3 Dec 1941)

Hello everyone, First off, I do not own the Kar 98k books (perhaps I should as the info may be there). Has anybody here obtained an electronic copy of Hitler's decree Wi/I F 5.117 from the Bundesarchiv-Militärarchiv ? It is dated 3 December 1941 and it is the starting point of the rifle...

Last edited:

Stephan98k

aka 8x57IS

Thanks Stephan! That was a comprehensive and likely exhaustive response. Those period documents give some excellent context to your theories.

You are very welcome heavy_mech and thank you, for your thoughts and contributions to the topic.

I wonder if the barrel code can provide a clue as to when these were assembled. I see in the KCN datasheet it's 40 Ru 95 and in the OP rifle it's 40 Ru 125. I can't see it in the photos from the auction, but I wonder if Nulle was the winner and whether he still has this?

So looking in the bible it appears that "by the b block of 1942, the barrel serial number had been eliminated". The OP doesn't show that photo, but the 2 examples Loewe shared both have the barrel serial which would lead me to believe these were assembled before 1942.

Looking at reported barrel codes, 40 Ru 4 was used on 4448b and 40 Ru 133 appears on 4175f in 1940, so it would seem that lot #s 95 and 125 could certainly be in the d block of 1940 production. I think that exact barrel code pattern might be important in dating these.

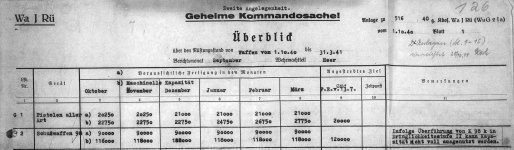

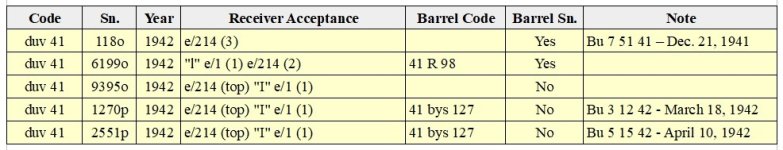

The examples you mentioned are the following K98k:

The assumption is that you would expect a built-in barrel with the codes "40 Ru 95" and "40 Ru 125" in the "d" block of production in 1940. Maybe I would have guessed the "d" or "e"block like you did.

Here is the K98k from our thread and the two other pieces that Paul luckily secured:

In some time periods, and especially for manufacturers who have continuously produced K98k, this type of assessment with barrel codes works very well. As you know, I have worked intensively on the laminate data and these are also very important for determining a period of time.

However, sometimes this is only possible to a limited extent due to the previously mentioned difficulties such as production delays and production stops. In addition, Gustloff-Werke has taken over some of BSW's old stock, which Bruce already mentioned.

Here are three examples to illustrate the problem at this time:

The first example from1940 with the Sn. 1898 has a Ruhrstahl barrel from 1938. The "bcd41" Sn. 4091c was assembled in 1941 and it has a Ruhrstahl barrel from 1940, even the lot number "40 Ru 133" matches your example. A run from the same lot, even though there are several months and around 100,000 K98k between these two pieces. Also the"bcd 42" Sn. 5694b has a Ruhrstahl barrel from 1940. But I don't want to portray the barrel codes and laminate codes as useless.Even if it seems chaotic, we have also gained insights from it.

In the thread with theSSZZA4 rework I had already mentioned the catastrophic situation with the Ruhrstahl barrels and that manufacturers had difficulties in assembly and increased rejects as a result. Since it fits the topic and provides better understanding, I have picked out various Ruhrstahl examples and I would like to share them with you.

Volume II Chapter I Page 52

On the page 52 there is a document from August 1942 and a very good explanation, here is a short excerpt:

"The companies with the highest rejection percentages were Ruhrstahl and Berlin-Lübecker-Maschinenfabrik."

Volume II Chapter I Page 27

The document shown therefrom May 1941 is also interesting, it concerns a tolerance request for the steel chemistry of material for the production of rear sight leaf. Mauser Oberndorf had submitted an request to tolerate a little higher concentration of phophorus in the steel and to use this material in the production. The tolerance request was accepted by the Heeres-Abnahmestelle.

In general, the acceptance was still very strict in 1941 and a lot was relaxed in 1942. As a result, from 1942 onwards, some parts could be used that had previously been rejected by the HWa.

Volume II Mauser Oberndorf Chapter Page 139

A document from Mauser Oberndorf from June 1939 about problems with Ruhrstahl barrels. Jon Speed's comment is great as always.

Volume II Mauser Oberndorf Chapter Page 142

Another important document on this topic from October 1942. It is about allowing the release of barrel blanks that contain tungsten. Here is a short excerpt from the book:

"In the case of the K98k, by late 1942 the material situation forced an evaluation of all available steel barrel blanks in inventory at Oberndorf."

Volume II Mauser Oberndorf Chapter Page 198

Another example with a Mauser Oberndorf "1943 Banner Commercial K98k". Here is the short excerpt from the book:

"The barrel blank was supplied by Ruhrstahl AG and was completed in 1938 (38R11 barrel code). This barrel was likely held in inventory and not used in military production due to a process defect or out of tolerance condition but was deemed usable for assembly with this rifle."

By the way, the "Circle A" rifles that I know of also all have Ruhrstahl barrels, with one exception having a Döhlen barrel.

These examples for Ruhrstahl should be enough and they also show how late some barrels were used in production in order to get back to the original topic and the questions asked about it. I hope this explanation and also the things mentioned in my previous post help to understand why I put thiese K98k in 1942 and not in 1940. But those weren't the only reasons, there more things that speak in favor of my theory and I will show them.

In my diagram you could clearly see the development when, from June 1941, the declining production numbers of K98k and the excessive demands of the Luftwaffe led to the so-called Rifle Crisis. Here are some very important quotes from my first post and what impact they had:

"But also in 1941there was no continuous K98k assembly in Weimar because the armament was again redirected, this time it was the Führerbefehl (Adolf Hitler directive) No. 32 from June 11, 1941."

"Due to the redirection of armaments production and a shortage of workers,assembly of the K98k at the Fritz-Sauckel-Werk in Weimar was stopped in 1941. Here is an excerpt from the book "Die Inzenierung der Stadt Weimar - Planen und Bauen im Nationalsozialismus in Weimar"by Karina Loos about this topic:

"In 1940, the Fritz-Sauckel-Werk received a wartime contract directly from the Oberkommando der Wehrmacht (High Command of the Armed Forces) to produce K98k carbines, and in 1941 it also received an order to build a production facility to manufacture 2cm-Flak 38 including accessories and spare parts, which was intended to be financed by the Oberkommando der Wehrmacht.

Due to the shortage of workers, the “Waffenschmiede” (Armory) of the Gau capital Weimar, the “Fritz-Sauckel-Werk”, had stopped producing the 98k carbine.Due to the high increase in the need for weapons, resumption of production from February 1942 was considered."

As already mentioned,the redirection of armaments production was the main reason for the shutdown of K98k assembly at the Fritz-Sauckel-Werk in 1941. There were many parts in stock because more K98k were supposed to be assembled, but due to the interruptions they were not immediately used in production and therefore many parts are not linear but mixed.In this context, I would like to remind you again of the sentence "In many companies there is already a buildup of half-finished weapons that cannot be further processed and assembled because individual parts are missing." from the document dated March 15, 1940."

Here are our various guesses about the time period when these pieces were assembled. Each of these comments is important:

This may be a legit left over BSW receiver used in 1940 Gustloff production.

.. two others known, BSW/38 receivers with at least one a Ruhrstahl 1940 coded blanks, e/749 acceptance RR, top final e/749 (BSW Suhl didn't TF and bcd not until late1941) and these are probably assembled mid-late 1941 at Weimar.

I also found the offset top final odd. The RR does look correct and that '40 dated barrel would seem to support what Loewe said.

These posts are very important and I agree with everything except the year 1940 and 1941. In my opinion this receiver was used in 1942 Gustloff production.

The Gustloff K98k assembly did not run continuously and was interrupted in 1940 and 1941. The reason is the redirection of armaments through an order from July 13, 1940 by Adolf Hitler. In June 1941 the armament was again redirected to the detriment of the K98k - which was also one of the reasons that led to the so-called "Rifle Crisis" in 1941/1942. Many of the "bcd41" coded K98k were assembled in 1942 after a longer interruption.

The Waffenamt document TL-1/1003 K98k inspection standard is very useful to date changes etc., in our case to assume the assembly date. The Waffenamt changed to top final on January 28, 1942.

Stephan, if this rifle was assembled in 1942, why the 40 dated barrel and full receiver inspection suite of Waffenamt stamps.

This seems to have been assembled well before the rationaliziation orders were implemented in early 1942.

Stephan, much of my post was guessing based upon very few facts coupled with extrapolations.... I do agree it could be 1942 but trends do not suggest this yet.

So looking in the bible it appears that "by the b block of 1942, the barrel serial number had been eliminated". The OP doesn't show that photo, but the 2 examples Loewe shared both have the barrel serial which would lead me to believe these were assembled before 1942.

As I said at the beginning, your contributions are very important and I agree with everything, I just have a different opinion about the time period. Inmy opinion, these K98k can only come from the 1942 assembly and I would like to show you the reasons why.

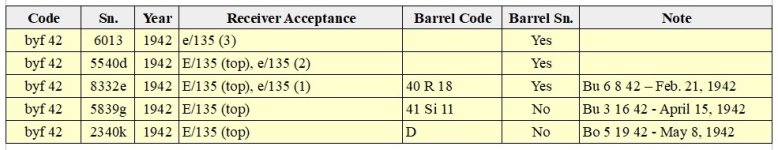

We have already touched on the topic of laminate date codes and now we will come back to this topic and our trends in general. Please take a look at the following piece and pay attention to the notes:

The above matching numbered K98k is pictured in the Volume II book and it is because of the laminate date code "BR 5 33 41" a very good example. This code means "August 15, 1941" and that means that this K98k could only have been assembled after this date. My estimate for assembly is Spring 1942, but I don't want to rule out late December1941 either. Here are two quotes on this topic from the Volume II book:

Volume II Gustloff-Werke Chapter Page 539

"Normally thestock completion date precedes the final assembly of the K98k by somemonths but this delay time varied between manufacturers. At a minimumthe stock completion dates can approximate the date of assembly butare also useful in determining the authenticity of the K98k."

Volume II Berlin-Lübecker Maschinenfabrik Chapter Page 485

"The stock date gives an approximate completion date for the rifle. The stock dating for BLM appears to correlate closer to the assembly date of the rifle verses other K98k contractors where the final assembly of the rifle could post-date the stock code by several months."

The above mentioned “bcd41” Sn. 9245i could have been assembled in December, althoughI lean towards Spring 1942. The highest serial number I know of is"bcd 41" Sn. 7573p and if the "i" block can hardly have been assembled in December 1941, then it is more than unlikely with the later ones. We have the complete "k","l", "m", "n", "o" block, which would be 50,000 K98k and then an additional 7,573 K98k from the"p" block. Given the capacity of the Gustloff-Werke at the time, this would mean more than two months of assembly time. I would also like to remind you again of the production stop in 1941 and the quote from the book "Die Inzenierung der Stadt Weimar -Planen und Bauen im Nationalsozialismus in Weimar". Please look again at all the reasons I listed, the documents and examples from production, I hope we can agree that a large part of the "bcd41" coded Gustloff-Werke K98k were assembled in 1942.

Here are a few more examples from the assembly of the Gustloff-Werke to make it clearer:

It is very important that you look at the comments in the “Notes”. These anomalies do not exist in the 1941 production and even if one were to ignore all the reasons I mentioned earlier, these three K98k with the "BSW1938" receivers would fit perfectly into this 1942 "oddball group".

Stephan, if this rifle was assembled in 1942, why the 40 dated barrel and full receiver inspection suite of Waffenamt stamps.

This seems to have been assembled well before the rationaliziation orders were implemented in early 1942.

Bruce, please look again at the table above with my examples, especially the "bcd 41" Sn. 4794n, I marked this in blue for you. Also "bcd 41" Sn. 4794n has the complete set of acceptances and top final, like the rifles with the "BSW 1938" receivers. Below are the relevant rifles again in a smaller table.

It can be assumed that these pieces with the BSW receivers were assembled in the late "m" block, shortly before the transition to the top final acceptance and then they were inserted into the assembly line in the "d" block. That sounds strange and the Oddball group in the table above is not enough for you? Then please take a look at the following things:

Here we have a special piece, the 337 1940 Sn. 320mo:

https://www.k98kforum.com/threads/1940-gustloff-werke-k98k.55034/

The piece above has one ofthe highest known serial numbers for a "337 1940" and also has an FN barrel installed. Please remember when the factory was occupied by German troops and when production of K98k barrels began. The Laminate Code "Br 3 45 40" means November 6, 1940. A comment from Ryan on this piece:

That's really odd, and it looks intentional since the 'mo' is on all the major parts. It's not the usual 'm' you would see on an m block either.

The 'm' looks more like the larger 'm' you see on the Navy builds. I don't think this is KM though, it clearly is Gustloff production.

I don't know what to make of it.

Here we have another special one of these pieces, the "337 1940" Sn. 345oo:

https://www.k98kforum.com/threads/337-1940-matching.39036/

It's best to show someexcerpts from your comments on this piece, but please read the entirethread, it is very important to understand what was going on at theGustloff-Werke Weimar at the time.

The rifle is the highest recorded for Gustloff-Weimar in 1940, prior high's all in the n-block. Thing is it appears that nothing is factory except the receiver. The barrel is not Ruhrstahl or Geco, and all up through 1940 should be (one exception, an FN in the m-block, but this isn't FN either...).

Although Mauser-Berlin and SDP used a lot of Si barrels, the arrangement of the BC only fits Mauser-Oberndorf and the odds are strong (very high) that this is a barrel off a Mauser. Not an ordnance spare either as the only ordnance spares this early were G98 length, and Mauser rarely shipped barrels to others before 1943 (bcd-SDP), Mauser was very stingy with barrels, they used almost all in-house (and they could use a lot of barrels, no one beats Mauser making rifles...)