You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PTR44 Semi-Auto MP44

- Thread starter mrfarb

- Start date

PTR parts

Was talking to a PTR owner today about a new Dingo sourced carrier versus an original PTR part. We do not know for sure why some PTR carriers that came in the rifles broke. Obviously not every PTR broke its carrier but it would not surprise me if many of the guns sold have not been shot much if at all.

Could be the carriers are too hard/brittle from not having been drawn back enough after the heat treat quenching.

It's easy to Rockwell test one for hardness but the alloy used is unknown so even if one wanted to soften a carrier(or bolt) it would be a crap shoot as to the needed draw temp.

Owner said he was told the replacement carriers were properly done but no detail regarding what may have changed.

I know a guy that's a gun guy that is the metalurgest at a big pump manufacturer here in St. Louis. I think I'll ask him about all that and see what he thinks.

Pete

Was talking to a PTR owner today about a new Dingo sourced carrier versus an original PTR part. We do not know for sure why some PTR carriers that came in the rifles broke. Obviously not every PTR broke its carrier but it would not surprise me if many of the guns sold have not been shot much if at all.

Could be the carriers are too hard/brittle from not having been drawn back enough after the heat treat quenching.

It's easy to Rockwell test one for hardness but the alloy used is unknown so even if one wanted to soften a carrier(or bolt) it would be a crap shoot as to the needed draw temp.

Owner said he was told the replacement carriers were properly done but no detail regarding what may have changed.

I know a guy that's a gun guy that is the metalurgest at a big pump manufacturer here in St. Louis. I think I'll ask him about all that and see what he thinks.

Pete

Was talking to a PTR owner today about a new Dingo sourced carrier versus an original PTR part. We do not know for sure why some PTR carriers that came in the rifles broke. Obviously not every PTR broke its carrier but it would not surprise me if many of the guns sold have not been shot much if at all.

Could be the carriers are too hard/brittle from not having been drawn back enough after the heat treat quenching.

It's easy to Rockwell test one for hardness but the alloy used is unknown so even if one wanted to soften a carrier(or bolt) it would be a crap shoot as to the needed draw temp.

Owner said he was told the replacement carriers were properly done but no detail regarding what may have changed.

I know a guy that's a gun guy that is the metalurgest at a big pump manufacturer here in St. Louis. I think I'll ask him about all that and see what he thinks.

Pete

Looking at the surface finish and the moulding lines on my broken BD44 bolt makes me believe that these parts were not forged at all but simply die cast.

I contacted SSD for replacement parts but they were not interested at all to send me any and referred me to Wolverine supplies (one of the original importers in

Canada).

They tried for quite awhile to get the replacement parts with no success so in the end I replaced both the bolt and bolt carrier with original WWII parts.

The finish on these is totally different,the machining marks are clearly visible which was not the case with the SSD parts.

So in the end I finally have a perfect functioning BD44,but from my experience with SSD i would not trust any bolts or bolt carriers that were produced by them.

dingo

Senior Member

When the PTR s was made , the hardening was dun by another company. SSD did not have the equipment to do it then, after those problems they started doing the hardening them self. The PTR op rods was to brittle so they cracked.Was talking to a PTR owner today about a new Dingo sourced carrier versus an original PTR part. We do not know for sure why some PTR carriers that came in the rifles broke. Obviously not every PTR broke its carrier but it would not surprise me if many of the guns sold have not been shot much if at all.

Could be the carriers are too hard/brittle from not having been drawn back enough after the heat treat quenching.

It's easy to Rockwell test one for hardness but the alloy used is unknown so even if one wanted to soften a carrier(or bolt) it would be a crap shoot as to the needed draw temp.

Owner said he was told the replacement carriers were properly done but no detail regarding what may have changed.

I know a guy that's a gun guy that is the metalurgest at a big pump manufacturer here in St. Louis. I think I'll ask him about all that and see what he thinks.

Pete

dingo

Senior Member

Looking at the surface finish and the moulding lines on my broken BD44 bolt makes me believe that these parts were not forged at all but simply die cast.

I contacted SSD for replacement parts but they were not interested at all to send me any and referred me to Wolverine supplies (one of the original importers in

Canada).

They tried for quite awhile to get the replacement parts with no success so in the end I replaced both the bolt and bolt carrier with original WWII parts.

The finish on these is totally different,the machining marks are clearly visible which was not the case with the SSD parts.

So in the end I finally have a perfect functioning BD44,but from my experience with SSD i would not trust any bolts or bolt carriers that were produced by them.

It is impossible for SSD to send parts out of Germany without a lot of paperwork, that is why I did go down to Germany and picked up op rods. I send t them from my country to American customers that had broken op rods for free. Germany has very strict gun laws, bolts and barrels are very restricted so cant be exported without working with the state department. SSD has learn d a loot from the PTR problems, and that is why we are stocking up parts in USA before new rifles hits the marked. When it comes to production , SSD also have more experience now and makes better products. I have newer heard of any problem s with the replacement op rod s I send t to USA.

Last edited:

KDF82

Senior Member

Thanks Dingo, with that said my unfired PTR is a wall hanger until I can replace parts. I can see on them where the hardness was tested. With the previous owner deceased no way to know how good they are until broken, or broken in. Hence original parts incoming. Pete, I hope your guy can shed some light.. Much appreciated. Oh, I also purchased one of the first batch of PTR 32s and my bolt head cracked after about 30 rounds.. Brittle, poor heat treatment..Hmmmm???

Intruder196

Senior Member

It is impossible for SSD to send parts out of Germany without a lot of paperwork, that is why I did go down to Germany and picked up op rods. I send t them from my country to American customers that had broken op rods for free. Germany has very strict gun laws, bolts and barrels are very restricted so cant be exported without working with the state department. SSD has learn d a loot from the PTR problems, and that is why we are stocking up parts in USA before new rifles hits the marked. When it comes to production , SSD also have more experience now and makes better products. I have newer heard of any problem s with the replacement op rod s I send t to USA.

Speaking of replacement parts, I see your site list the BD44 stock ferrule. I need one of these but was wondering if you could tell me if they are made from steel? The one I have is aluminum and cracked. I don't need another aluminum one.

GunKraut

Senior Member

Speaking of replacement parts, I see your site list the BD44 stock ferrule. I need one of these but was wondering if you could tell me if they are made from steel? The one I have is aluminum and cracked. I don't need another aluminum one.

I bought one. It's steel.

What you bought is an airsoft or ATI .22 ferrule.

Intruder196

Senior Member

I bought one. It's steel.

What you bought is an airsoft or ATI .22 ferrule.

Mine came with an original parts set I got years ago. It had everything but a magazine. The stock and ferrule were repro but I didn't know who made them. My thought was they are like you said above or a Shoei repro.

I went ahead and ordered one just now. How long did shipping take for yours?

Last edited:

dingo

Senior Member

Speaking of replacement parts, I see your site list the BD44 stock ferrule. I need one of these but was wondering if you could tell me if they are made from steel? The one I have is aluminum and cracked. I don't need another aluminum one.

It is steel. Yours was shipped today

sprat

Senior Member

With a fellow asking about 2200 for an original Op Rod and bolt now, I'm happy I've got that covered until I can get the parts from Dingo. Ideally it's backup. If I ever let that kit go I'll keep it complete. I'll see how it shoots before I send it to Pete as I enjoy building as well as fixing them. HKs and G43s have taught me a lot. You said you had a parts source for the 45 kit. Were you talking mags or receiver?

PM sent on the replacement

My new oprod/carrier arrived from Dingo today. The packaging was way more than was probably necessary and it was packed well enough to survive being run over. Thanks for such care Dingo! It slid right into the receiver and was a perfect fit. I'll take it out to the range for testing this weekend. It differs in a few areas cosmetically but otherwise looks to be nearly identical down to the machining marks on the bottom behind the unlocking claws. It had a few small (really small) rust spots on it but they'll clean right off and any marks left behind just adds to the patina if you ask me. While the original is all blued, this one is a mixture of finishes. The cocking handle and piston are bright steel while the carrier itself is a dull grey. I guess it's blued but it's almost the color of graphite. Whatever the finish is, I like it better as it looks more like a vintage part. Anywho, all I care about is whether or not it holds up. Dingo says it is warranted and others have contacted me speaking very highly of both him and replacement parts that he has supplied so I am very optimistic. Let's take a look. These pictures show the replacement part as it came out of the wrapping with no oil applied.

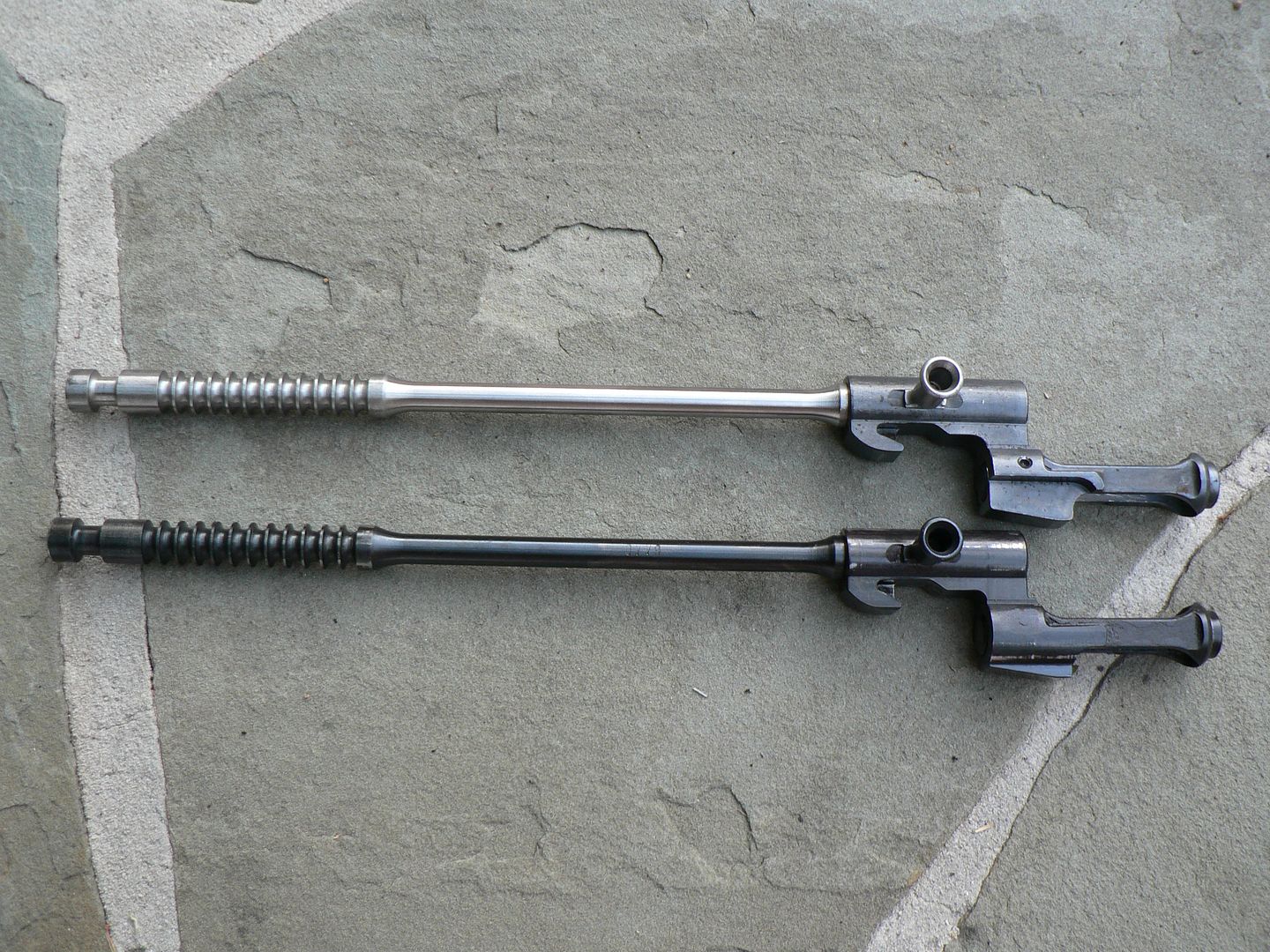

The new replacement part is on top:

Replacement on the right:

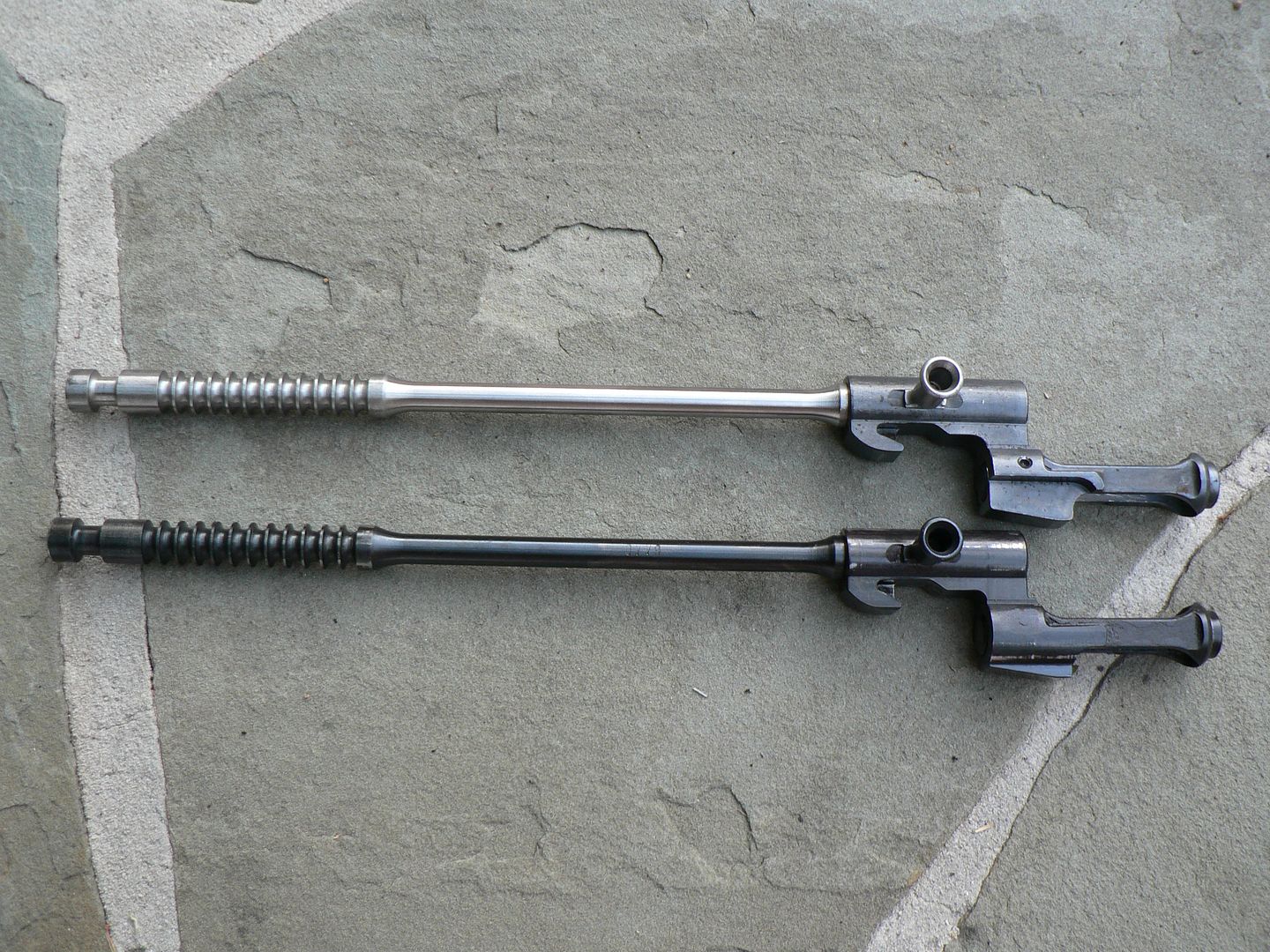

Replacement on bottom:

The new part is closer to the camera so the charging handle diameter looks to be larger. As far as I can tell, they are actually the same size.

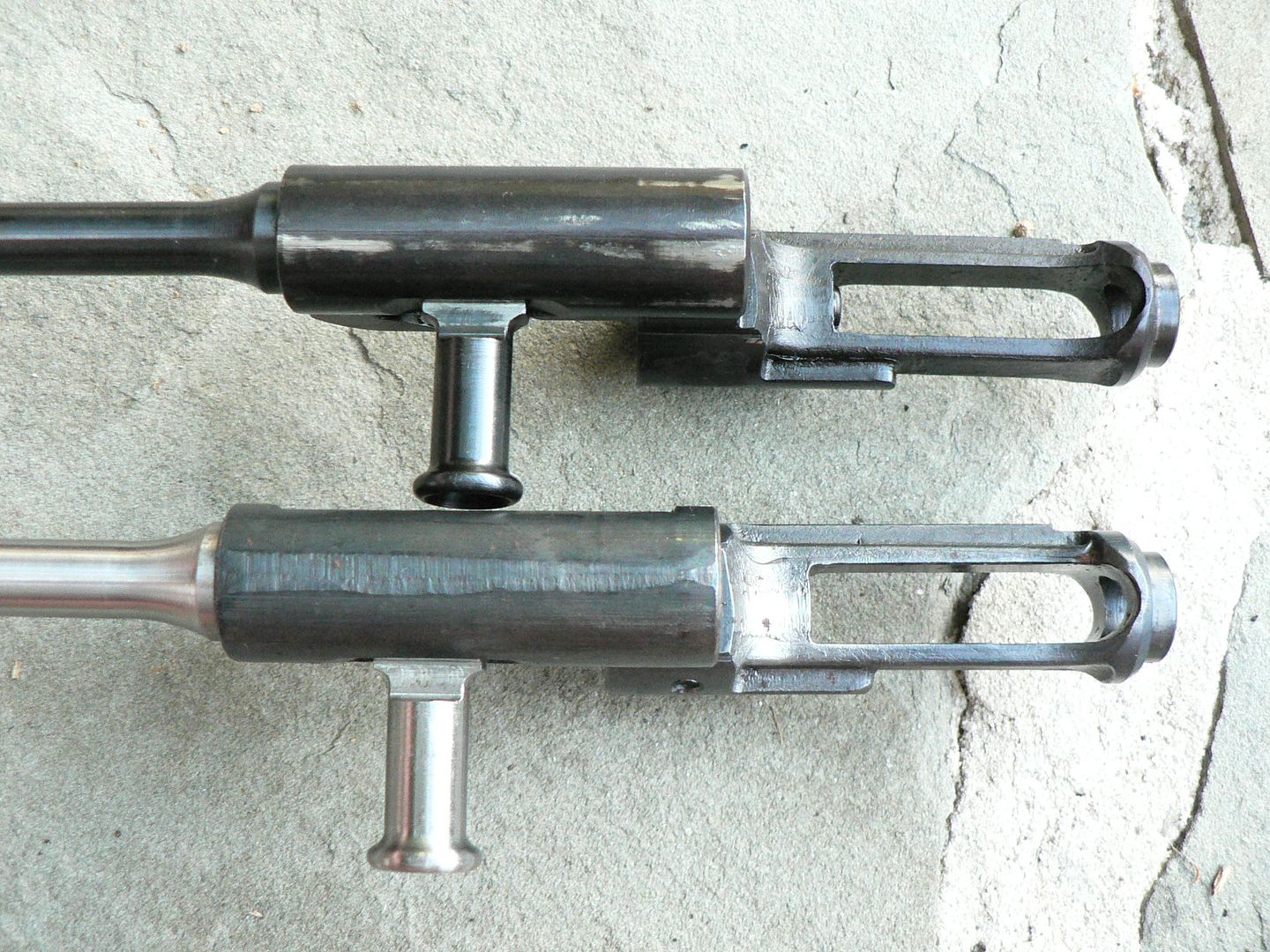

Replacement on bottom. Notice the graphite grey color compared to the black on the one that is numbered to the rifle. Also notice that the upper one has its intermediate firing pin retaining pin ground flush:

Replacement is on bottom:

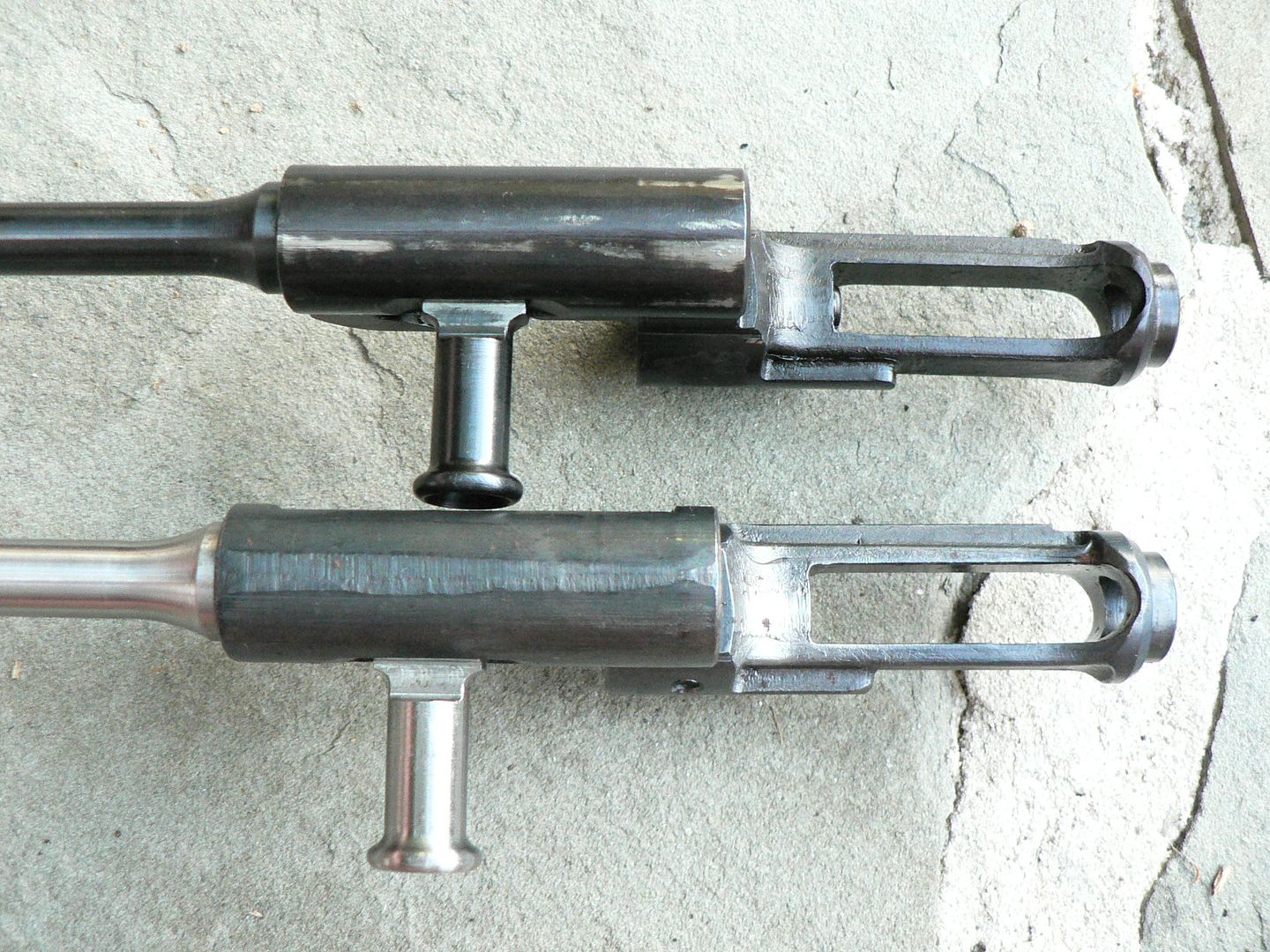

Replacement on the left. Notice that the machining marks behind the unocking claws are very similar. The webbing on the new part is a bit beefier than the numbered one I think. When engaging the claws on the bolt with the claws on the carrier, there seems to be less side to side movement on the new one.

The new part looks good and seems to fit perfectly. Time will tell but, as I said, Dingo says the part is guaranteed so I am very optimistic. It was expensive but I don't care so long as it works. Thanks for what you are doing Dingo!

The new replacement part is on top:

Replacement on the right:

Replacement on bottom:

The new part is closer to the camera so the charging handle diameter looks to be larger. As far as I can tell, they are actually the same size.

Replacement on bottom. Notice the graphite grey color compared to the black on the one that is numbered to the rifle. Also notice that the upper one has its intermediate firing pin retaining pin ground flush:

Replacement is on bottom:

Replacement on the left. Notice that the machining marks behind the unocking claws are very similar. The webbing on the new part is a bit beefier than the numbered one I think. When engaging the claws on the bolt with the claws on the carrier, there seems to be less side to side movement on the new one.

The new part looks good and seems to fit perfectly. Time will tell but, as I said, Dingo says the part is guaranteed so I am very optimistic. It was expensive but I don't care so long as it works. Thanks for what you are doing Dingo!

KDF82

Senior Member

My new oprod/carrier arrived from Dingo today. The packaging was way more than was probably necessary and it was packed well enough to survive being run over. Thanks for such care Dingo! It slid right into the receiver and was a perfect fit. I'll take it out to the range for testing this weekend. It differs in a few areas cosmetically but otherwise looks to be nearly identical down to the machining marks on the bottom behind the unlocking claws. It had a few small (really small) rust spots on it but they'll clean right off and any marks left behind just adds to the patina if you ask me. While the original is all blued, this one is a mixture of finishes. The cocking handle and piston are bright steel while the carrier itself is a dull grey. I guess it's blued but it's almost the color of graphite. Whatever the finish is, I like it better as it looks more like a vintage part. Anywho, all I care about is whether or not it holds up. Dingo says it is warranted and others have contacted me speaking very highly of both him and replacement parts that he has supplied so I am very optimistic. Let's take a look. These pictures show the replacement part as it came out of the wrapping with no oil applied.

The new replacement part is on top:

Replacement on the right:

Replacement on bottom:

The new part is closer to the camera so the charging handle diameter looks to be larger. As far as I can tell, they are actually the same size.

Replacement on bottom. Notice the graphite grey color compared to the black on the one that is numbered to the rifle. Also notice that the upper one has its intermediate firing pin retaining pin ground flush:

Replacement is on bottom:

Replacement on the left. Notice that the machining marks behind the unocking claws are very similar. The webbing on the new part is a bit beefier than the numbered one I think. When engaging the claws on the bolt with the claws on the carrier, there seems to be less side to side movement on the new one.

The new part looks good and seems to fit perfectly. Time will tell but, as I said, Dingo says the part is guaranteed so I am very optimistic. It was expensive but I don't care so long as it works. Thanks for what you are doing Dingo!

Thank you Wilhelm.. Here are some shots of my original numbered Op. No bluing and subtle differences to your original. Original owner deceased so no telling if these have been worked over though it is slightly different from yours. I've got original and Dingo replacement parts en-route. I can't say enough kind words about Dingo as he's saving the PTR crowd.

Open question to anyone running BFAs.. I purchased one from AWB and another loaned from a friend, also AWB with an Original MP44. Neither will thread onto the barrel more than two revolutions before lockup. Ran a M14x1.0 tap down both and original muzzle nut just fine. Have any other PTR owners had these issues?

Attachments

KDF82

Senior Member

You did not mention that the replacement part has been cut for actuating a F/A sear. That could become something of an issue down the road.

Good call! I knew there was something odd but didn't have any wartime parts to quickly compare... discount double check!

You did not mention that the replacement part has been cut for actuating a F/A sear. That could become something of an issue down the road.

Yes,looks identical to WWII part,may even be original,obviously the gas piston is a recent reproduction.

But since the trigger group has no F/A parts in it and would be hard even to modify for F/A it should not be a problem