I don't know of any documents on a direct connection between commercial proof procedures and military proof procedures because AFAIK there was none.

Obviously, both systems had the same goal, to ensure that firearms in the hands of the users were safe, but I know of no direct comparisons between the two systems. Further, the commercial proof systems in countries like England and Germany were established by public law and the standards published as public documents, where the military system was established by military regulations which were rarely made public or widely published. (And sometimes are misunderstood when they are!)

It is sometimes said that military proof testing was not done, or was done only on samples due to the need for high production. That might have been true in 1945 when many standards slipped, but it was certainly not true earlier, even though some inspection steps were eliminated sooner. Besides, for obvious reasons, no government wants to issue possibly defective guns to its troops. (We might recall the serious morale problem among Canadian troops when a design defect in the Ross rifle resulted in some accidents.)

Yes, the German barrel proof was similar to the provisional proof or temporary proof in that the idea was to weed out any defective barrels before they were assembled into a gun. The U.S. did exactly the same thing, with a "P" stamp on the barrel (of, say, an M1 rifle) indicating the barrel proof while the circled "P" on the stock indicated that the gun had passed its final definitive proof. I had a picture someplace of the barrel proof setup for the .45 caliber M1911A1 pistol barrel; I can't find it right now, but it is a fixture with a lever inside what looks like a barbeque grill with a heavy metal cover. The barrel was clamped into the fixture, the proof load put in the chamber, the lever turned down to close the toggle "breech", the cover closed, and the "gun" fired. Failures were, I understand, rare but they did happen, and would have destroyed an expensive pistol if the barrel proof had not been done. BTW, back to Germany, the Luger and P.38 pistols were also subject to barrel proof.

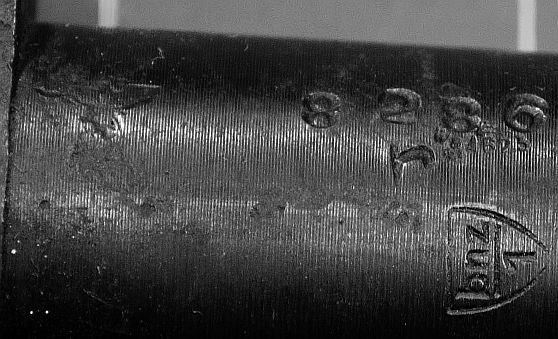

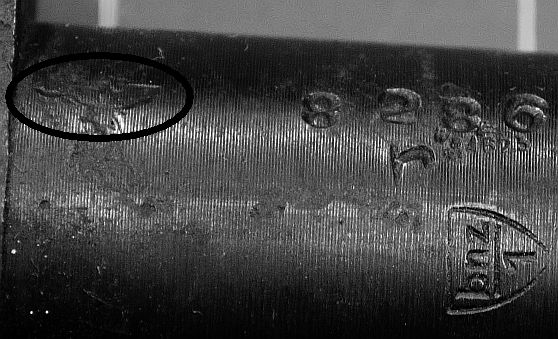

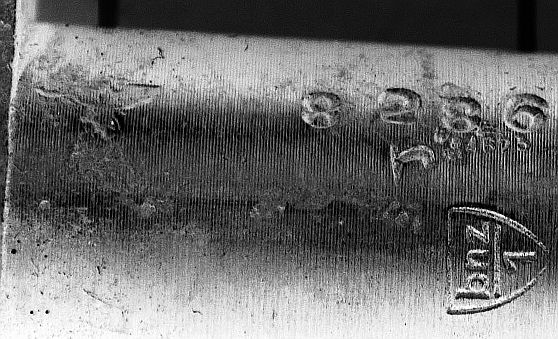

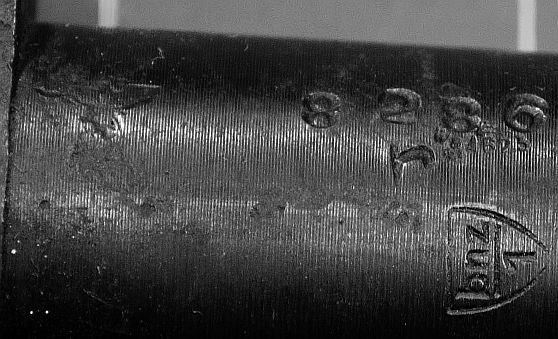

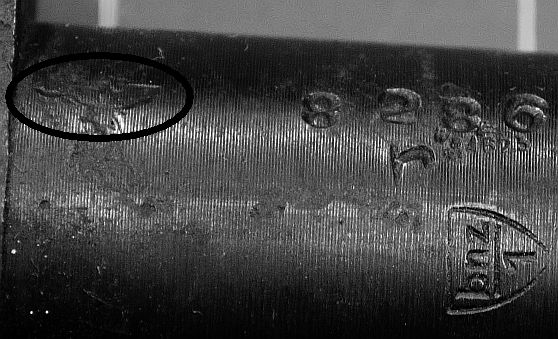

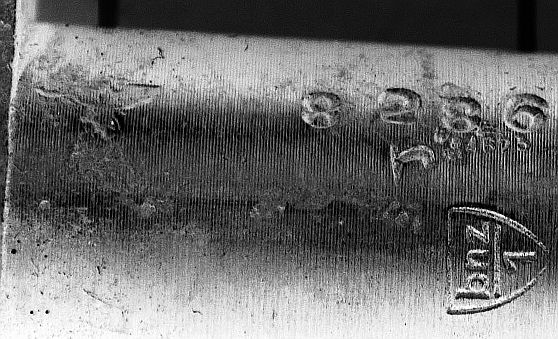

An element of confusion with German barrel proofs is that usually the same size and type of eagle was used as was used for the final proof mark on the receiver. That is understandable because there were certain specified sizes and the stamps were issued by (in this period) the WaA. So it looks like an inspector stamped the receiver and the barrel at the same time, when in fact the barrel had been proved and stamped in the barrel shop before even being assembled to the receiver. Sometimes we do see clearly different stamps, and collectors who believe that both were made at the same time by the same person don't understand how that could happen.

Jim