Cyrano4747

Well-known member

Here is something I didn't expect to have in my collection for a very, very long time.

A while ago I spotted a Gunbroker auction for two salvage-grade Gew71/84s. Here is the listing photo:

I've been idly looking at all sorts of trash 71/84's for a while in the vain hope that I might spot an Oberndorf in need of some love, and that day I hit the jackpot. The one with no wood was an Oberndorf.

Even more happily it wasn't in near as bad shape as the rust bucket Amberg that came along for the ride. The general condition when I got my hands on it was filthy, but very little actual rust. Here are a couple of shots that should give you a feel for the general shape.

I wish I had taken a picture of the inside of the receiver before I removed the lifter arm, it was caked full of some really foul dirt or mud or something, and fragments of what appeared to be old paper. I feared the worst, but it wasn't locked up.

The lifter arm and part of the trigger assembly after sitting in a jar of mineral spirits for a week. Happily the crud you see still on there scraped off easily with a custom made brass scraping tool (aka a cartridge flattened on an anvil) with no major pitting.

The gun is obviously incomplete. The front sight and the rear sight ladder were both missing (although the flip up v-notch, rear sight pin, and spring were all present), the stock and all of its hardware are obviously distant memories, and the magazine tube, follower, and spring are also MIA. On the up side the trigger guard, magazine components (spoon, selector, etc), trigger, and all the associated small parts were there and matching.

The really ugly part is that the under-barrel lug that locks the magazine tube and front barrel band in place was removed:

I did a test fitting with a stock and magazine I pulled off a shooter Spandau. The good news is that if you're just setting up for something to look right you can still install the magazine and stock without that lug, but it still bugs me. I've got a fix in the works for this that I'll detail once I get it fully worked out.

Based on that and the extreme bluing wear to the underside of the front of the barrel (where it would normally be covered by the stock) I believe this gun was sporterized at some point, likely when these were being imported as cheap surplus by the likes of Bannerman:

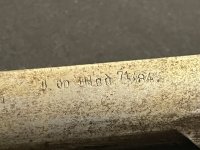

I've completely torn down the rifle and given it an extremely thorough detail cleaning. I'll post up some pics of the gun as it is now and the various markings on it in a bit. I've already replaced some parts (the front and rear sight) with bits salvaged from the junker Amberg up above, and I have everything else I need to put this gun right on order. Well, "right" in the appropriate number of scare quotes. Obviously I'm never getting correct Waffenfabrik Mauser parts, these things are exceedingly rare as it is. But I'll complete it and put it back into military trim at the very least.

Doing the math on the replacement parts, some materials I've needed to fix bits that needed repair, and the cost of the gun itself I figure that when it's all said and done I'll be into this to the tune of about $800, maybe $850. Not bad to finally get an Oberndorf 71/84, even if it's not a complete, matching example.

I'll update in a moment with details on the markings, small parts, etc. as well as the work I've done so far.

A while ago I spotted a Gunbroker auction for two salvage-grade Gew71/84s. Here is the listing photo:

I've been idly looking at all sorts of trash 71/84's for a while in the vain hope that I might spot an Oberndorf in need of some love, and that day I hit the jackpot. The one with no wood was an Oberndorf.

Even more happily it wasn't in near as bad shape as the rust bucket Amberg that came along for the ride. The general condition when I got my hands on it was filthy, but very little actual rust. Here are a couple of shots that should give you a feel for the general shape.

I wish I had taken a picture of the inside of the receiver before I removed the lifter arm, it was caked full of some really foul dirt or mud or something, and fragments of what appeared to be old paper. I feared the worst, but it wasn't locked up.

The lifter arm and part of the trigger assembly after sitting in a jar of mineral spirits for a week. Happily the crud you see still on there scraped off easily with a custom made brass scraping tool (aka a cartridge flattened on an anvil) with no major pitting.

The gun is obviously incomplete. The front sight and the rear sight ladder were both missing (although the flip up v-notch, rear sight pin, and spring were all present), the stock and all of its hardware are obviously distant memories, and the magazine tube, follower, and spring are also MIA. On the up side the trigger guard, magazine components (spoon, selector, etc), trigger, and all the associated small parts were there and matching.

The really ugly part is that the under-barrel lug that locks the magazine tube and front barrel band in place was removed:

I did a test fitting with a stock and magazine I pulled off a shooter Spandau. The good news is that if you're just setting up for something to look right you can still install the magazine and stock without that lug, but it still bugs me. I've got a fix in the works for this that I'll detail once I get it fully worked out.

Based on that and the extreme bluing wear to the underside of the front of the barrel (where it would normally be covered by the stock) I believe this gun was sporterized at some point, likely when these were being imported as cheap surplus by the likes of Bannerman:

I've completely torn down the rifle and given it an extremely thorough detail cleaning. I'll post up some pics of the gun as it is now and the various markings on it in a bit. I've already replaced some parts (the front and rear sight) with bits salvaged from the junker Amberg up above, and I have everything else I need to put this gun right on order. Well, "right" in the appropriate number of scare quotes. Obviously I'm never getting correct Waffenfabrik Mauser parts, these things are exceedingly rare as it is. But I'll complete it and put it back into military trim at the very least.

Doing the math on the replacement parts, some materials I've needed to fix bits that needed repair, and the cost of the gun itself I figure that when it's all said and done I'll be into this to the tune of about $800, maybe $850. Not bad to finally get an Oberndorf 71/84, even if it's not a complete, matching example.

I'll update in a moment with details on the markings, small parts, etc. as well as the work I've done so far.