I'm in the process of building a semi MP-44. Always wanted one but could never afford one. Considered using a Cetme but decided not to. Then Dingo brought the flats in. I couldn't hit the buy button fast enough. So that was the start of the build.

I gradually bought some parts. Others I made or will make.

Bought a GM 8mm barrel blank and a Manson 7.92x33mm reamer and gauges.

Then made a bending jig. After I bent the flat so far I realized I couldn't get the trunnion in. At the time I wasn't aware that the Germans stuck the trunnion in and then completed bending it. Once I opened up the flat the trunnion was put back in and then the flat completely closed up. And then welded where needed.

Previously KSH67 lent me some original parts. Particularly the bolt. So I used that and drawings to make a bolt from AL. I tested it in the flat with the carrier in and a trial barrel. It worked. The real bolt will be made out of 8620 alloy and case hardened.

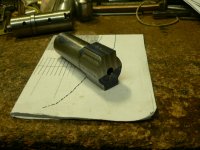

I just finished profiling the already chambered barrel. I used the drawing specs but used the ID's of the trunnion , gas block, and front sight to get those journal dimensions.

So now the barrel is done except for that feed ramp in the breech and the gas port hole. The spec for the hole is .150". Which seems a bit large .

I intend to make the grip stick. Which should be fun. And I will make the fcg parts based on Mauser's simplified design of 1944.

I had talked to shortfal about a year ago about this build. He gave me very good advice. Thank's shortfal.

I'll post a picture of the receiver which is quite finished yet. Forgive some of the crappy welds. Some days they are great and other days not so much.

I gradually bought some parts. Others I made or will make.

Bought a GM 8mm barrel blank and a Manson 7.92x33mm reamer and gauges.

Then made a bending jig. After I bent the flat so far I realized I couldn't get the trunnion in. At the time I wasn't aware that the Germans stuck the trunnion in and then completed bending it. Once I opened up the flat the trunnion was put back in and then the flat completely closed up. And then welded where needed.

Previously KSH67 lent me some original parts. Particularly the bolt. So I used that and drawings to make a bolt from AL. I tested it in the flat with the carrier in and a trial barrel. It worked. The real bolt will be made out of 8620 alloy and case hardened.

I just finished profiling the already chambered barrel. I used the drawing specs but used the ID's of the trunnion , gas block, and front sight to get those journal dimensions.

So now the barrel is done except for that feed ramp in the breech and the gas port hole. The spec for the hole is .150". Which seems a bit large .

I intend to make the grip stick. Which should be fun. And I will make the fcg parts based on Mauser's simplified design of 1944.

I had talked to shortfal about a year ago about this build. He gave me very good advice. Thank's shortfal.

I'll post a picture of the receiver which is quite finished yet. Forgive some of the crappy welds. Some days they are great and other days not so much.