Fal Grunt

Senior Member

*** Idiot Lawyer Disclaimer ***

Don't be dumb. Do your best. It's all we can ask. Should you find yourself unsuccessful we accept no liability for your actions.

*** Idiot Lawyer Disclaimer ***

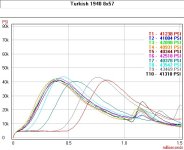

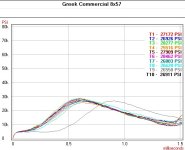

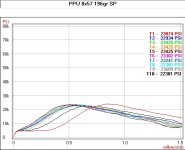

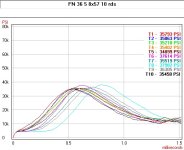

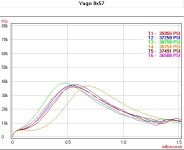

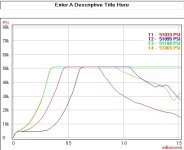

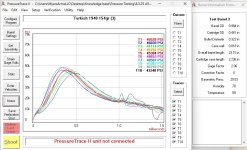

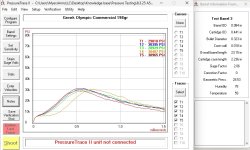

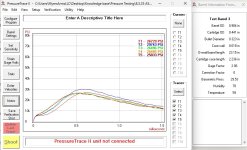

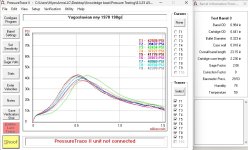

For several years I have been doing pressure testing mostly revolving around heat treating and metallurgy in regards to Mauser actions. This fall I wanted to run some more standard numbers and look at several variants regarding pressure curves and velocities. This is part of a larger project, but I need a base line for comparison first.

For testing I built a rifle using specially selected components. The action is a Steyr Chilean contact 1912 receiver and bolt. I used these two because I knew exactly what the composition of the steel was and I could have them heat treated to exactly my specs. The receiver was heat treated to 45-50 Hrc and the bolt to 55-60 Hrc. This is the HIGH end of where you would want to heat treat an action. I wanted it on the cusp of being too hard. (Note – HRC is not correct for case hardened actions, these numbers are converted from Superficial for relevance)

The barrel for this project I selected to use a NOS Yugoslavian 8x57 barrel. I fit the barrel to the receiver with what some call “negative” headspace. That is, the bolt will not close on a GO gauge, but will close on ammunition, albeit tightly on crap ammo like Turk. The barrel was also slugged and the bore/groove numbers documented. The chamber was measured using Mauser’s method of measuring with gauge balls to measure for chamber growth. Being that it is a Yugoslavian barrel it measures 23.150” in length.

The chamber was measured using Mauser’s method of measuring with gauge balls to measure for chamber growth. Something I have found fascinating about metallurgy and headspace, most rifles with excess headspace, appear to be a result of chamber growth. This measurement allows me to verify expansion from an over pressure event. With this particular testing, I won't be doing any over pressure instances, but I like to measure and have a baseline just in case.

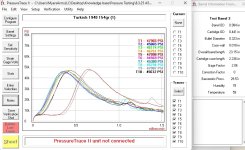

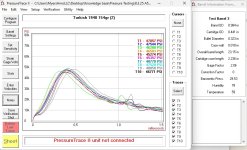

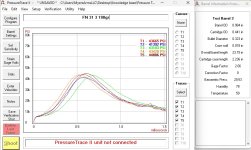

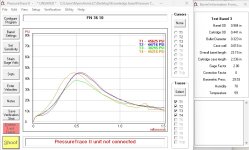

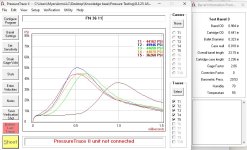

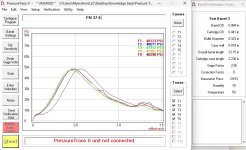

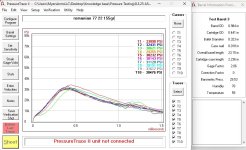

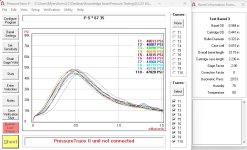

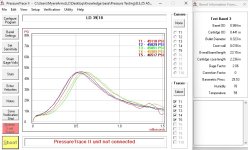

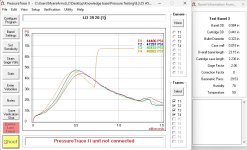

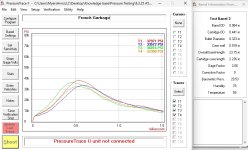

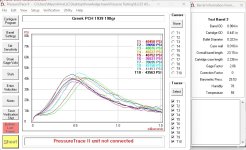

To measure the pressure a Pressure Trace II is used. This system uses a strain gauge to measure the flex of the barrel and calculate the internal pressures. This system has been a lot of fun to use and to learn. When I was doing destructive testing I ran into several issues and had several long conversations with the man who created and built these systems. He was initially shocked and seriously concerned at what I was doing, because I was doing exactly the opposite of what any safe and sane person would do. After we talked for awhile we identified two different issues with my research. First was that the system was not setup to read as high as I wanted it to (80k psi +) and second that the results I was getting seemed to truncated. That is, they should have been showing higher pressure curves but were not. After I eliminated the software issue, I sent more results, which he showed were the limits of the elasticity of the steel.

The gauges are mounted directly over the chamber and using special glue, attached to the barrel. The electrical tape serves absolutely no purpose other than to make myself feel better. Tearing the tiny wires off of a $35 strain gauge mid test is mildly irritating. Careful measurements are taken of the barrel and chamber for the system to use to calculate pressure.

As a side note I am still looking for some Beschusspatrone. There were some on gunbroker for $250/box but I wasn't willing to pay that. A partial box, 3 to 5 rounds is really all that is needed, but I would buy a full box if someone has one they would like to sell.

Don't be dumb. Do your best. It's all we can ask. Should you find yourself unsuccessful we accept no liability for your actions.

*** Idiot Lawyer Disclaimer ***

For several years I have been doing pressure testing mostly revolving around heat treating and metallurgy in regards to Mauser actions. This fall I wanted to run some more standard numbers and look at several variants regarding pressure curves and velocities. This is part of a larger project, but I need a base line for comparison first.

For testing I built a rifle using specially selected components. The action is a Steyr Chilean contact 1912 receiver and bolt. I used these two because I knew exactly what the composition of the steel was and I could have them heat treated to exactly my specs. The receiver was heat treated to 45-50 Hrc and the bolt to 55-60 Hrc. This is the HIGH end of where you would want to heat treat an action. I wanted it on the cusp of being too hard. (Note – HRC is not correct for case hardened actions, these numbers are converted from Superficial for relevance)

The barrel for this project I selected to use a NOS Yugoslavian 8x57 barrel. I fit the barrel to the receiver with what some call “negative” headspace. That is, the bolt will not close on a GO gauge, but will close on ammunition, albeit tightly on crap ammo like Turk. The barrel was also slugged and the bore/groove numbers documented. The chamber was measured using Mauser’s method of measuring with gauge balls to measure for chamber growth. Being that it is a Yugoslavian barrel it measures 23.150” in length.

The chamber was measured using Mauser’s method of measuring with gauge balls to measure for chamber growth. Something I have found fascinating about metallurgy and headspace, most rifles with excess headspace, appear to be a result of chamber growth. This measurement allows me to verify expansion from an over pressure event. With this particular testing, I won't be doing any over pressure instances, but I like to measure and have a baseline just in case.

To measure the pressure a Pressure Trace II is used. This system uses a strain gauge to measure the flex of the barrel and calculate the internal pressures. This system has been a lot of fun to use and to learn. When I was doing destructive testing I ran into several issues and had several long conversations with the man who created and built these systems. He was initially shocked and seriously concerned at what I was doing, because I was doing exactly the opposite of what any safe and sane person would do. After we talked for awhile we identified two different issues with my research. First was that the system was not setup to read as high as I wanted it to (80k psi +) and second that the results I was getting seemed to truncated. That is, they should have been showing higher pressure curves but were not. After I eliminated the software issue, I sent more results, which he showed were the limits of the elasticity of the steel.

The gauges are mounted directly over the chamber and using special glue, attached to the barrel. The electrical tape serves absolutely no purpose other than to make myself feel better. Tearing the tiny wires off of a $35 strain gauge mid test is mildly irritating. Careful measurements are taken of the barrel and chamber for the system to use to calculate pressure.

As a side note I am still looking for some Beschusspatrone. There were some on gunbroker for $250/box but I wasn't willing to pay that. A partial box, 3 to 5 rounds is really all that is needed, but I would buy a full box if someone has one they would like to sell.