I’m finally putting together the 1916 WOK I picked up here as a project.

It only had the rear action screw so I picked up another original set from another member.

Cleaned and lubed all the threads first. Rear screw threads in fine. Front screw gets tighter and tighter as it goes in (not cross threaded) but will not go in full depth.

Visual inspection shows that the threads look a little off but not goobered up. Of the three action screws I have loose all thread into the rear hole and all struggle with the front hole. I’d like to chase that front hole.

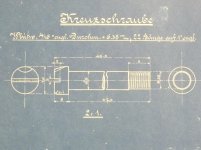

A simple bolt gauge shows 6mm to be a good size and thread pitch to be metric 1.5…but…wanting to double check myself I did some googling and see that 1/4-22 is supposedly the size (confirmed on this site by a member who did some pretty accurate measurements).

Can anyone confirm that 1/4-22 is actually the best choice for this issue? If I run a tap down into the thread hole to clean it up will I need to chase the apparently good threads on the screw with 1/4-22 also or will the factory threads work in the 1/4-22 chased hole?

I have tried generously lubing the screw threads and then slowly working it into the hole past the point of resistance then backing it out and repeating. Made some headway but it ultimately bound up too hard to force.

It only had the rear action screw so I picked up another original set from another member.

Cleaned and lubed all the threads first. Rear screw threads in fine. Front screw gets tighter and tighter as it goes in (not cross threaded) but will not go in full depth.

Visual inspection shows that the threads look a little off but not goobered up. Of the three action screws I have loose all thread into the rear hole and all struggle with the front hole. I’d like to chase that front hole.

A simple bolt gauge shows 6mm to be a good size and thread pitch to be metric 1.5…but…wanting to double check myself I did some googling and see that 1/4-22 is supposedly the size (confirmed on this site by a member who did some pretty accurate measurements).

Can anyone confirm that 1/4-22 is actually the best choice for this issue? If I run a tap down into the thread hole to clean it up will I need to chase the apparently good threads on the screw with 1/4-22 also or will the factory threads work in the 1/4-22 chased hole?

I have tried generously lubing the screw threads and then slowly working it into the hole past the point of resistance then backing it out and repeating. Made some headway but it ultimately bound up too hard to force.

Last edited: