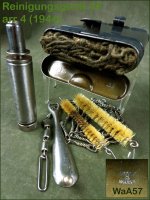

I've been watching kits off and on for a while myself, and have come to notice some peculiarities myself about arr kits. It's very difficult to know exactly what parts belong in late kits but I've noticed a trend with the stamped oilers. These stamped sheetmetal oilers are mostly in the arr4 kits with the WaA392 inspection. The arr4 kits with WaA57 inspection mostly have the spoons from Kyffhäuserhütte and the simplified steel type oilers, and the arr4 kits with WaA20 are not seen as often by me so I can't say for sure. What I'm getting at, I think the waffenamt WaA57 were all actually put together by Kyffhäuserhütte and not as some say with parts provided to Brauchschweigische Blechwarenfabrik by Kyffhäuserhütte. Also, i'd bet money that the WaA20 kits should have G Appel type parts in them.

I'm really starting to believe the scenario that arr4, rco44, and rco45 cans were supplied to 2 other makers other than Brauchschweigische Blechwarenfabrik for assembly by them, and that only Brauchschweigische Blechwarenfabrik used the sheetmetal type oilers. In this case, only those actually assembled by Brauchschweigische Blechwarenfabrik might have the sheetmetal oiler, any kits assembled by the others might never have them.

I readily admit that it's nearly impossible to know who assembled kits with no acceptance on them. I have never "studied" kits to the degree to write a book, this is from casual observations.

I'm really starting to believe the scenario that arr4, rco44, and rco45 cans were supplied to 2 other makers other than Brauchschweigische Blechwarenfabrik for assembly by them, and that only Brauchschweigische Blechwarenfabrik used the sheetmetal type oilers. In this case, only those actually assembled by Brauchschweigische Blechwarenfabrik might have the sheetmetal oiler, any kits assembled by the others might never have them.

I readily admit that it's nearly impossible to know who assembled kits with no acceptance on them. I have never "studied" kits to the degree to write a book, this is from casual observations.