As far as the bore sizes go , just look at real rifles . Everyone who has ever measured a bore found their's matched what I said . I have measured several hundred rifles and seen the original German military documents and ballistic tests , and they match would I have found in the real rifles . He has not checked real rifles and just gets his tech info from other people's books .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steyr 1890

- Thread starter k98dave

- Start date

Nothing wrong with reliance on other peoples books... you have your specialty and have the tools and mechanical skills to do your research. In some ways it is a more "noble" method in that it is more individualistic than other methods used, but you are not infallible and and conclusions often take on a life of their own (at least with most people, - most people tend to get attached to conclusions they form over time and though it helps when your livelihood or status doesn't rest on the "right" conclusions reached or maintained it can be equally blinding to other possibilities, or even probabilities).

Anyway, even though you are one of the most brash collectors I have seen at times your research and self-confidence is quite entertaining (generally) and well worth toleration as self-confidence is always (almost) appealing in an author or researcher (I never read a book I truly respected when the author was too accommodating or mealy-mouthed, and no one can attribute that to you and your conclusions...)

Anyway, even though you are one of the most brash collectors I have seen at times your research and self-confidence is quite entertaining (generally) and well worth toleration as self-confidence is always (almost) appealing in an author or researcher (I never read a book I truly respected when the author was too accommodating or mealy-mouthed, and no one can attribute that to you and your conclusions...)

AndyB

Senior Member

Problem by the rifles is that they are more time refurbished, by germans and later in export countries, so wout real german or other countries archives You couldnt say what was done with the rifles in last 100 years, certainly should be used only quality books from skilled researchers of real german and other countries documents, with combination of real measuring of well preserved rifles is the best way to find answers. Stoerz or older Goetz are skilled authors not as any authors that wrote only about few guns that they saw and photographed.

From german archives of army using is clear that G88 was one of the worsest design in german army used (many soldiers were injured), which were after short life already refurbished on various stages. Standing of the twist in barell was very low, when compare the Mod.98, other point is that the period was of quick change of ammunition developing.

From german archives of army using is clear that G88 was one of the worsest design in german army used (many soldiers were injured), which were after short life already refurbished on various stages. Standing of the twist in barell was very low, when compare the Mod.98, other point is that the period was of quick change of ammunition developing.

Last edited:

The problem is when the info in the books is provable to be wrong . " Facts " written in many books - .318 groove bore [ never was ] , charger guides riveted on [ no through hole so mechanically not possible { I have installed 10's of 1000's of rivets of many types in my life om everything from airplane wings , race car bodies and truck frames } , and I knocked one off and you could clearly see the plug weld , plus if you look at enough rifles you can see some with a little flame cut on the edge of the ground down plug weld { you guys should check your rifles for it ] , the S on the receiver means it was a Gew-88 S [ not true ] , only the later .323 Z barrels were used for S ammo [ even though I have many real Gew-88 S rifles with the older .3208 barrel ]. The 05 notch was cut for the " longer " S ammo [ S ammo is shorter and the notch is clearly cut to clear the older P-88 ammo and that is stated in German manuals ] , the dot stamp means reinforced barrel [ German manuals say it was the new barrel nut solder , I have rifles with the original thin matching barrels and no dot , plus I only have jacket removal problems with no dot rifles ] . Since I know what the markings mean , I know original German parts , the upgrades that match the markings and so on . Things just said that are wrong . The Gew-88 and the Gew-98 have the exact same twist rate , I have measured many . From 1896 1/2 the Gew-88 and the Gew-98 used the same exact spec barrels . How many have you measured , and do you even know how ? Most German Gew-88 rifles spent their whole life as made b[ the most common is still the plain Gew-88 ] . Many were used from their birth right though WWI . After the first ammo / powder problem was solved they were fine . There is no reports from WWI of a failure rate any greater the the Gew-98 . They were in German service from 1889 to 1918 , almost 30 years , not too short a life . I have spent countless hours with a friend who has all the original manual and document from Germany and a degree in imperial German language . I have compared all my 100 plus rifles [ plus many others ] with my mechanical skills to his documents . I have disassembled all, cut up some . So all my info comes from original document , a large amount of real rifles and ammo, and hands on measuring . Exactly how you said it should .

AndyB

Senior Member

I have studied historical info about Austrian and Czechoslovak items and could say here to correct some opinions, that austrian made only rifles and barells with and for origin old P88 cartridge, never went to spitz round S1905, got in WW1 mainly G88 rifles as ally help from Germany, in inventory are not any G88/05 or G88/14 reported, same as Czechoslovakia never had in inventory interesting numbers of G88, never send large ammounts of G88 rifles to South America, only barell and spare parts to Turkey and other countries, this is certainly not mentioned in any of the german manuals.

The mentioned info about replacement of barells by german army was brought from Goetz so when he is wrong in some points, ok. Anyway in some parts he only reproduced original german archive documents. But maybe some of his conclusion about marking on guns are wrongly interpreted.

The mentioned info about replacement of barells by german army was brought from Goetz so when he is wrong in some points, ok. Anyway in some parts he only reproduced original german archive documents. But maybe some of his conclusion about marking on guns are wrongly interpreted.

Last edited:

Fal Grunt

Senior Member

The problem is when people don't cite their sources. You state that you have access to all the original manuals and drawings, tremendous! Why are you wasting your time typing the same argument over and over and over again. Post the primary documents, along with your rifles and measurements. Easy!The problem is when the info in the books is provable to be wrong . " Facts " written in many books - .318 groove bore [ never was ] , charger guides riveted on [ no through hole so mechanically not possible { I have installed 10's of 1000's of rivets of many types in my life om everything from airplane wings , race car bodies and truck frames } , and I knocked one off and you could clearly see the plug weld , plus if you look at enough rifles you can see some with a little flame cut on the edge of the ground down plug weld { you guys should check your rifles for it ] , the S on the receiver means it was a Gew-88 S [ not true ] , only the later .323 Z barrels were used for S ammo [ even though I have many real Gew-88 S rifles with the older .3208 barrel ]. The 05 notch was cut for the " longer " S ammo [ S ammo is shorter and the notch is clearly cut to clear the older P-88 ammo and that is stated in German manuals ] , the dot stamp means reinforced barrel [ German manuals say it was the new barrel nut solder , I have rifles with the original thin matching barrels and no dot , plus I only have jacket removal problems with no dot rifles ] . Since I know what the markings mean , I know original German parts , the upgrades that match the markings and so on . Things just said that are wrong . The Gew-88 and the Gew-98 have the exact same twist rate , I have measured many . From 1896 1/2 the Gew-88 and the Gew-98 used the same exact spec barrels . How many have you measured , and do you even know how ? Most German Gew-88 rifles spent their whole life as made b[ the most common is still the plain Gew-88 ] . Many were used from their birth right though WWI . After the first ammo / powder problem was solved they were fine . There is no reports from WWI of a failure rate any greater the the Gew-98 . They were in German service from 1889 to 1918 , almost 30 years , not too short a life . I have spent countless hours with a friend who has all the original manual and document from Germany and a degree in imperial German language . I have compared all my 100 plus rifles [ plus many others ] with my mechanical skills to his documents . I have disassembled all, cut up some . So all my info comes from original document , a large amount of real rifles and ammo, and hands on measuring . Exactly how you said it should .

Fal Grunt

Senior Member

Here, I will give you an example.

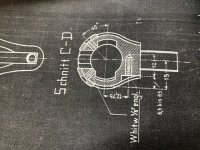

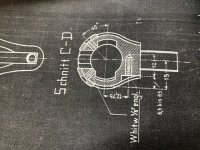

I will submit the following, showing the 88/05 updates as specified by Spandau, that the charger guides should be attached by a threaded screw. Pictured also is a Gewehr 88/05 that I cut apart, to show the attachment method. When I complete the write up, included will also be the Spandau work instructions which match exactly to the Mauser work instructions.

Now you can present your primary documents and real world examples showing that they were welded.

I will submit the following, showing the 88/05 updates as specified by Spandau, that the charger guides should be attached by a threaded screw. Pictured also is a Gewehr 88/05 that I cut apart, to show the attachment method. When I complete the write up, included will also be the Spandau work instructions which match exactly to the Mauser work instructions.

Now you can present your primary documents and real world examples showing that they were welded.

Last edited:

Your photos are interesting . The one I cut off was clearly plug welded . I have the photos somewhere and will look for them . So it looks like they may have done it two ways , or different per arsenals , or time periods . But it still proves the were not riveted as stated in many books .

Good back & forth, I do not care who is right, only that the subject is furthered to potential conclusions or certainties... this the purpose we always saw for the forum, politeness & common interest is nice but free expression and actual proof trumps all.

Ernie, Andy and Fal Grunt are first rate researchers!

Ernie, Andy and Fal Grunt are first rate researchers!

Fal Grunt

Senior Member

I look forward to seeing your primary documents on the welded charger guides as well as the example rifle(s).Your photos are interesting . The one I cut off was clearly plug welded . I have the photos somewhere and will look for them . So it looks like they may have done it two ways , or different per arsenals , or time periods . But it still proves the were not riveted as stated in many books .

It is very possible, and given further research, might be demonstratable, that as the 88's were worked through the larger arsenals and smaller quantities were required, they were sent to smaller companies who were given variances allowing different procedures. This is the key function of sharing primary documents and research. I have copies of the Amberg and Spandau drawings, as well as the Mauser conversion instructions. The Mauser instructions match the Spandau document verbatim. There are a total of 14 new acceptance stamps marked on an 88/05, with 49 gauges to test fit and function. By sharing your primary documents we may be able to narrow down the list and better determine who could have, or could not have done the work.

Similarly, each of your above issues, we can work through singularly, and identify who (what books, published when, by who), and why the error was published. The only book I have, and the only book I know of on the 88 is Storz. I would have to read through it again to see if he calls the guide riveted. We may find, that like your welded example, there are examples that are riveted. Riveting would be much more economical than the screw, and for a company with less technical abilities, may be a more reasonable approach.

Some of the errors are understandable, visually I can absolutely understand someone mistaking the screw head, sans slot, for a rivet. Similarly, I can understand someone with little to no machining background looking at the groove diameter on a drawing, converting 8.1mm to .3188", and calling it a ".318". The vast majority of people struggle with land/groove geometry, especially when you consider the ambiguity in the US for using either land or groove diameter when naming a cartridge or bullet diameter.

The point is, by sharing your information, the entire community is elevated.

AndyB

Senior Member

Goetz on pg.103 wrote that the G88/05 rework was done in ammount of 200000 pcs in Gewehrfabriken in period 1906/7 as quality refurbishment, it costed 8Mark per rifle.

I personally same opinion that for someone not skilled similar special twist screw assembly with removed head, probably hammered and polished to other surface, wout any possibility to remove it could be by not skilled in mashinery call as riveting, this is certainly not removable screw assembly.

The G88/14 was declared on same page as welded on area of clip slot, because of war period and quickly needs to convert large number of rifles.Since 1917 were both designs declared as obsolete and were sold or send to ally mainly to Turkey and Bulgaria.

I personally same opinion that for someone not skilled similar special twist screw assembly with removed head, probably hammered and polished to other surface, wout any possibility to remove it could be by not skilled in mashinery call as riveting, this is certainly not removable screw assembly.

The G88/14 was declared on same page as welded on area of clip slot, because of war period and quickly needs to convert large number of rifles.Since 1917 were both designs declared as obsolete and were sold or send to ally mainly to Turkey and Bulgaria.

Sorry , I have been away . I was on a long hunting / camping trip in the canyons of N Texas . No deer , some hogs at night with the thermal . The biggest disappointment was carrying around a Gew-88 with a good 400 yard zero for hogs but not seeing any in daylight . I have not seen your screw document before , I do like it . A ground down wedge screw . How overly complicated , and very precise of and operation . AND so German . I have no documents for the welding , just what I saw on a rifle . It has been about 20 years ago I started saying they were not riveted and knocked a guide off to prove it . That was about 2 PC's ago so I do not know where the photos are now .

As far as riveting goes . Of the 100's of rifles I have looked at I have never seen a hole on the inside of the receiver under the guide , nor a rivet head . As a riveter I do not know of a a way to attach with a rivet without a through hole . Someone can post a diagram to show how that can be done . It also may just be a different use of the term from then to now .

Finally got around to shooting it. I found some J bore bullets (.318) 175 grain soft nose and loaded with some light charges of IMR 4166 (2100 FPS) that shot about 6 MOA which was less than expected. Also loaded up some 125 grain .323 dia bullets with same powder load and groups tightened up to 4 MOA Plan to repeat using bullets for 32 Winchester150 grain RN which are ,321 Dia.